Mining conveyor belts are essential components in the extraction and transportation processes within the mining industry. These belts are specially designed to handle the rigorous demands of moving materials, such as ores and minerals, from deep underground to surface levels. Steel cord conveyor belts, in particular, play a pivotal role due to their superior strength and durability. They are crafted to withstand the harsh conditions of mining environments, which often involve abrasive materials, heavy loads, and long-distance transport. The use of steel cord conveyor belts significantly enhances productivity by facilitating continuous and reliable operations, and they contribute to safety by reducing the risks associated with material haulage. This introduction emphasizes how these specialized belts are integral to modern mining operations, boosting both efficiency and safety.

Design and Specifications

Detailed Description of Steel Cord Conveyor Belt Structures

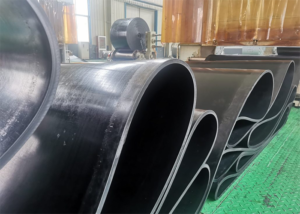

Steel cord conveyor belts are designed for high-strength and long-distance transportation of materials. The core structure of these belts consists of steel cords that are longitudinally arranged and embedded within a matrix of high-quality rubber. This unique construction provides a backbone that delivers exceptional tensile strength, making steel cord conveyor belts ideal for handling heavy loads.

Each steel cord is made from several strands of steel wire, twisted together to achieve the desired strength and flexibility. The exact number of strands and their diameter can vary depending on the specific requirements of the application. These cords are typically coated with a special rubber compound before being encased in the top and bottom covers of the belt, which protects the steel cords from environmental factors and reduces wear.

The top and bottom covers are themselves designed to withstand abrasion, tearing, and impacts. They are made from a variety of rubber composites, chosen based on the specific conditions under which the belt will operate. For instance, belts used in outdoor or chemical-exposure environments might use rubber materials that are specifically resistant to UV light, ozone, chemicals, and oils.

Key Specifications Impacting Performance

Tensile Strength: This is one of the most crucial specifications for steel cord conveyor belts, as it determines their ability to handle heavy loads over long distances without stretching excessively. Tensile strength is primarily provided by the steel cords, which are capable of sustaining high stress levels.

Durability: The life expectancy of a conveyor belt is largely dependent on its ability to resist wear and tear. The thickness and quality of the rubber covers play significant roles in protecting the core from abrasive materials and sharp objects encountered during operation.

Resistance to Harsh Conditions: Steel cord conveyor belts are renowned for their ability to perform in adverse environmental conditions. They can withstand extreme temperatures, exposure to chemicals, water, and UV radiation, making them suitable for diverse industrial applications, including mining, where such factors are prevalent.

Comparison with Nylon Conveyor Belts

Design Flexibility: Nylon conveyor belts are generally more flexible than steel cord belts. This flexibility allows them to be used on systems with smaller pulley diameters. It also makes them easier to handle and install, especially in tight spaces or configurations where the belt needs to wrap around corners and contours.

Suitability for Different Mining Conditions: While steel cord conveyor belts are favored for their high tensile strength and durability, especially in open-cast mining and for long-distance applications, nylon belts are often preferred in conditions where flexibility and lighter weights are required. For instance, in underground mining, where space constraints and sharp bends are common, nylon belts can offer better performance due to their ability to mold to the conveyor path.

When choosing between steel cord and nylon conveyor belts, considerations such as the mining environment, the nature of materials transported, and specific operational demands must be carefully evaluated. Steel cord belts, with their robust construction and high resilience, are generally suited for harsher, more demanding environments, whereas nylon belts offer advantages in applications requiring greater flexibility and ease of maintenance.

Cost Analysis

Factors Influencing the Price of Steel Cord Conveyor Belts

The cost of steel cord conveyor belts is influenced by several factors that impact their price point from production to market. Understanding these factors is essential for stakeholders to make informed purchasing decisions.

Material Costs: The primary cost driver for steel cord conveyor belts is the price of raw materials, notably steel wire and specialized rubber compounds. The global steel market volatility can significantly affect these costs, as the price of steel is susceptible to fluctuations based on international supply and demand dynamics. Similarly, the quality and type of rubber used for coating and protecting the steel cords can also vary in price, especially with variations in oil prices, as many synthetic rubbers are petroleum-based.

Manufacturing Processes: Steel cord conveyor belts require sophisticated and controlled manufacturing processes to ensure strength, durability, and performance. The process involves the precise alignment of steel cords, application of uniform rubber layers, and curing under specific conditions to ensure optimal adhesion and material properties. These processes are capital-intensive, requiring substantial investment in machinery and technology, which in turn contributes to the higher cost of these belts.

Market Demand: The demand for steel cord conveyor belts is heavily influenced by the mining, materials handling, and construction industries. High demand from these sectors can drive up prices, especially in regions where mining operations are expanding or where infrastructure projects are extensive.

Comparative Analysis with Other Types of Mining Conveyor Belts

Cost Comparison with Nylon Conveyor Belts: Nylon conveyor belts typically have lower initial costs compared to steel cord conveyor belts. The materials used in nylon belts—namely, fabric and rubber—are less expensive and less complex to process than the steel wires and specialized rubbers used in steel cord belts. Additionally, the manufacturing process for nylon belts is less energy-intensive and requires less sophisticated equipment.

Cost-effectiveness: While nylon conveyor belts may be less expensive upfront, the total cost of ownership must be considered when comparing the two. Steel cord conveyor belts often exhibit a longer lifespan and require fewer repairs and replacements in harsh mining environments, which can make them more cost-effective in the long run. The high initial investment in steel cord belts may be justified by lower maintenance costs and less frequent downtime.

Application Suitability: The choice between steel cord and nylon conveyor belts also depends on the specific application and operational requirements. In scenarios where high tensile strength and durability are required, such as in open-cast mining or for transporting particularly heavy or sharp materials, the higher cost of steel cord belts may be justifiable. Conversely, in applications requiring high levels of flexibility or for conveyance over shorter distances and less abrasive conditions, nylon belts may offer a more cost-effective solution without the need for the robustness provided by steel cords.

The decision between using steel cord and nylon conveyor belts in mining operations should consider both the initial purchase cost and the long-term operational costs. Factors like durability, application-specific requirements, and potential for maintenance and downtime should play critical roles in this cost analysis.

Installation and Maintenance

Challenges and Best Practices in the Installation of Steel Cord Conveyor Belts

Challenges:

Handling and Transportation: Due to their heavy weight and stiffness, steel cord conveyor belts present significant challenges in handling and transportation. Installing these belts often requires specialized equipment such as cranes and spreader bars to safely and efficiently maneuver them into place.

Alignment: Proper alignment is critical to ensure the smooth operation and longevity of steel cord conveyor belts. Misalignment during installation can lead to uneven wear, increased stress on the conveyor system, and eventual breakdown.

Splicing: Splicing steel cord belts is a complex procedure that requires precise technique and skilled technicians. Incorrect splicing can compromise the integrity of the belt, leading to premature failure.

Best Practices:

Use of Specialized Equipment: Employ cranes, hoists, and other specialized lifting devices to handle steel cord belts during installation. Ensure all personnel are trained in the safe operation of this equipment.

Precision in Alignment: Utilize laser alignment tools and professional installation crews to ensure the belt is accurately aligned along the conveyor structure. This reduces wear and tear and enhances operational efficiency.

Expert Splicing: Employ experienced technicians to perform splicing, using high-quality materials and the latest techniques. Consider using pre-spliced belts when possible to minimize on-site splicing requirements.

Detailed Maintenance Requirements and Tips

Maintenance Requirements:

Regular Cleaning: Keep the belt and conveyor components free from debris and buildup, which can cause damage and inefficiency.

Lubrication: Ensure that all moving parts of the conveyor system are regularly lubricated to reduce friction and wear.

Tension Adjustment: Monitor and adjust the tension of the steel cord belt regularly to prevent slippage and to ensure efficient power transmission.

Maintenance Tips:

Scheduled Downtime: Plan for regular maintenance shutdowns to perform thorough inspections and necessary repairs without rushing, which can prevent small issues from becoming major problems.

Use of Condition Monitoring Tools: Implement technologies such as vibration analysis, thermography, and wear detection systems to monitor the condition of the belt and associated machinery in real time.

Training for Maintenance Staff: Provide ongoing training for maintenance personnel to keep them updated on the latest maintenance practices and technologies.

Role of Routine Inspections and Preventive Maintenance

Routine Inspections:

Regular inspections are vital for identifying potential issues before they lead to failure. These should include visual checks, as well as more detailed assessments using tools like ultrasonic testers and x-rays to detect internal damage.

Inspection Frequency: The frequency of inspections should be increased in harsh operating environments or when the conveyor is used intensively.

Preventive Maintenance:

Systematic Approach: Develop a systematic preventive maintenance schedule based on the manufacturer’s recommendations and real-world operating conditions. This schedule should include periodic replacements of wear parts, tension adjustments, and intensive cleaning.

Proactive Repairs: When issues are identified during routine inspections, address them immediately rather than waiting for a scheduled maintenance period. This proactive approach can significantly reduce the likelihood of unscheduled downtime.

Reducing Operational Downtime:

Implementing a robust routine inspection and preventive maintenance program is key to minimizing operational downtime. By catching and addressing potential issues early, operations can avoid prolonged disruptions and ensure that the conveyor system operates at peak efficiency. Additionally, maintaining a stock of essential spare parts can drastically reduce downtime in the event of a part failure.

Proper installation and diligent maintenance are essential for maximizing the lifespan and efficiency of steel cord conveyor belts in mining operations. By adhering to best practices and embracing a proactive maintenance strategy, companies can optimize their conveyor systems’ reliability and operational uptime.

Case Studies

In-depth Examples of Steel Cord Conveyor Belt Applications in Major Mining Projects

Case Study 1: The Iron Ore Mega-Mine in Western Australia

In one of the largest open-cast iron ore mines in Western Australia, steel cord conveyor belts are employed to transport vast amounts of ore across extensive distances. This mining operation utilizes a series of interconnected conveyor systems that span several kilometers. The belts are subjected to abrasive iron ore and harsh environmental conditions, including extreme temperatures and high levels of dust.

Application Details: The steel cord belts used in this project are designed for high tensile strength and are capable of carrying loads exceeding 20,000 tons per day. They feature a specialized rubber compound that is highly resistant to abrasion and tearing.

Outcome: The deployment of steel cord conveyor belts in this project has resulted in a significant reduction in maintenance downtime. Compared to previous nylon belt systems, the steel cord belts have demonstrated superior durability and have decreased the frequency of belt replacements due to wear and tear.

Case Study 2: Gold Mining Operation in the Andes Mountains

A challenging gold mining operation located in the Andes utilizes steel cord conveyor belts to transport ore from the mine down steep inclines to the processing plant below. The belts are specially designed to handle the vertical and horizontal curves of the conveyor path, which includes angles that would be unmanageable for less robust belts.

Application Details: The conveyor system features high-strength steel cord belts that are engineered to withstand both the weight of the gold ore and the mechanical stresses induced by the conveyor’s steep, curvy descent.

Outcome: Steel cord belts were instrumental in overcoming the geographical challenges presented by the mountainous terrain. Their superior tensile strength and flexibility compared to nylon belts allowed for a more efficient and reliable transport system, reducing both operational costs and mechanical failures.

Highlighting Specific Scenarios Where Steel Cord Conveyor Belts Have Provided Significant Advantages

Scenario 1: High Load Capacity in Coal Mining

In a coal mining operation in Eastern Europe, the introduction of steel cord conveyor belts replaced older nylon belts, primarily to increase the load capacity and reduce the incidence of belt slippage. The steel cord belts were selected for their ability to handle higher loads without significant elongation.

Specifics: The belts are capable of transporting over 15,000 tons of coal per day over a 3-kilometer distance, a capacity increase of approximately 50% over the previous nylon belts.

Advantages: The increased load capacity and reduced elongation under load have resulted in fewer stoppages and a smoother flow of coal from the mine to the processing facility, enhancing overall efficiency.

Scenario 2: Durability in Harsh Environmental Conditions

A copper mine located in the deserts of Chile faced significant challenges with their conveyor belts due to abrasive materials and extreme temperatures. The shift to steel cord conveyor belts from nylon was crucial in addressing these issues.

Specifics: The steel cord belts implemented in this scenario are designed to withstand temperatures ranging from -20°C to +40°C and are treated with a UV-resistant rubber compound.

Advantages: The enhanced durability of the steel cord belts in extreme weather conditions and against abrasive materials resulted in a notable decrease in maintenance and replacement costs. The robust nature of the belts also contributed to an increase in overall productivity by minimizing unexpected operational disruptions.

These case studies demonstrate the specific advantages of using steel cord conveyor belts in demanding mining environments where their superior load capacity and durability provide tangible benefits over nylon conveyor belts, translating into cost savings and operational efficiencies.