Precision is essential in today’s manufacturing industry. From delicate aircraft components to complex medical gadgets, the need for precision and efficiency has never been greater. To fulfill these demands, the combination of Computer Numerical Control (CNC) machining and robotics has emerged as a disruptive force. This post digs into the collaborative link between CNC machining and robotics, examining how automation is transforming precise production.

Understanding CNC Machining

CNC machining is the use of computer-controlled machinery to precisely cut, carve, and shape materials including metal, plastic, and wood. Traditional machining techniques involve manual operation, which reduces productivity and precision. CNC machines, on the other hand, automate this process by utilizing computer-aided designs (CAD) to make exact motions at high speeds and accuracy. This automation decreases human error and allows for the creation of extremely intricate parts with strict tolerances.

The Role of Robotics

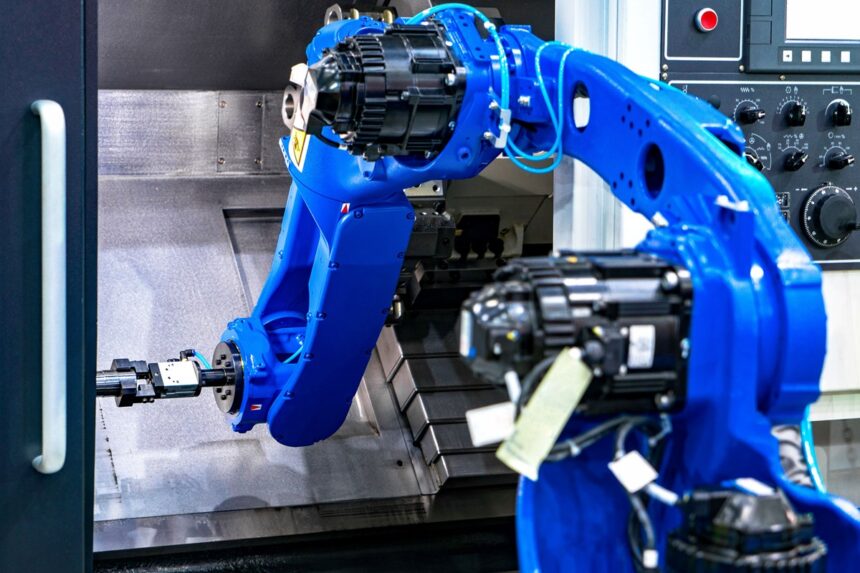

Robotics, on the other hand, adds additional flexibility and efficiency to manufacturing operations. Industrial robots are programmable machines with mechanical arms and specialized tools that can execute a variety of activities, including assembly and material handling. Integrating robotics into manufacturing operations boosts efficiency by reducing repetitive jobs and lowering cycle times.

The Intersection

CNC machining and robotics combine precision and automation. By combining the precision of custom CNC machining with the versatility of robotics, manufacturers may achieve unparalleled levels of efficiency and quality in their manufacturing processes. This synergy may be seen across a variety of industries, as complicated components are created quickly and consistently.

Automating Precision

One of the key benefits of combining CNC machining and robotics is the ability to automate precision. CNC machines excel at carrying out complex machining operations with micron-level precision. When combined with robotic automation, this equipment can work constantly, 24/7, with little human interaction. This not only lowers labor costs but also ensures uniform quality and consistency in manufacturing.

Improved Efficiency

Automation minimizes the need for manual intervention in repetitive operations, allowing manufacturers to improve their production processes for greater efficiency. Robots can load and unload workpieces, change tools, and execute secondary operations effortlessly, reducing downtime and increasing throughput. This increased productivity means shorter lead times, cheaper production costs, and more overall profitability.

Enhanced Safety

Safety is a top priority in manufacturing facilities. Robotics help to make the workplace safer by automating repetitive and potentially dangerous jobs like heavy lifting or exposure to hazardous materials. This not only protects workers from injury, but it also decreases the possibility of errors that could jeopardize product quality or lead to costly mishaps.

Adapting to Complexity

As industrial requirements become more complicated, robotics’ adaptability becomes increasingly important. CNC machines are excellent at making intricate parts with high precision, but they may struggle with tasks requiring flexibility or adaptability. Manufacturers can address this difficulty by incorporating robotics into precision CNC machining workflows and automating tasks like product inspection, assembly, and packaging.

The Future of Manufacturing

As industrial requirements become more complicated, robotics’ adaptability becomes increasingly important. CNC machines are excellent at making intricate parts with high precision, but they may struggle with tasks requiring flexibility or adaptability. Manufacturers can address this difficulty by incorporating robotics into CNC machining workflows and automating tasks like product inspection, assembly, and packaging.

Challenges and Opportunities

While the benefits of automated precision production are obvious, several hurdles must be overcome. Manufacturers may encounter integration challenges, high upfront expenses, and staff displacement. However, by adopting automation and investing in training and upskilling programs, businesses can obtain a competitive advantage in the global marketplace.

Advanced Materials Handling

Incorporating robotics into CNC machining workflows allows for enhanced material handling capabilities. Industrial robots with advanced grippers and vision systems can effectively handle raw materials and workpieces of various shapes, sizes, and weights. This versatility enables manufacturers to broaden their capabilities beyond standard machining methods, offering up new opportunities in areas such as automotive, electronics, and consumer goods.

Scalability and Flexibility

Incorporating robotics into CNC machining workflows allows for enhanced material handling capabilities. Industrial robots with advanced grippers and vision systems can effectively handle raw materials and workpieces of various shapes, sizes, and weights. This versatility enables manufacturers to broaden their capabilities beyond standard machining methods, offering up new opportunities in areas such as automotive, electronics, and consumer goods.

Data-Driven Optimization

The integration of CNC machining and robotics allows for data-driven process optimization. Sensors and monitoring systems enable firms to collect real-time data on machine operation, product quality, and energy consumption. Analyzing this data enables preemptive maintenance scheduling, predictive quality control, and continuous improvement efforts. Manufacturers can use data analytics to enhance production workflows, eliminate waste, and maximize resource utilization, resulting in operational excellence and long-term growth.

Conclusion

The combination of CNC machining with robotics represents a significant shift in precise production. By leveraging automation, firms may attain unparalleled levels of efficiency, quality, and safety in their manufacturing operations. As technology advances, the future holds enormous promise for additional innovation and growth in automated precision manufacturing, propelling progress and prosperity across industries worldwide.