In the modern cutthroat world where we see new buzz in the innovation of new technologies with drone class being no exception, propellers are vital and key parties in the flight dynamics, performance, and efficiency of the aircraft.

When one is using drones for fun, business purposes, or industry, choosing a propeller that will fit your requirements can be a huge plus.

One of the leading pioneer companies in drone components known as MEPSKING has created some of the best stable and performing propellers currently in the market.

This article will also describe the drone propeller in detail, the existing types, and how MEPSKING propellers enhance drone flight performance.

Understanding Drone Propellers: It’s basic features

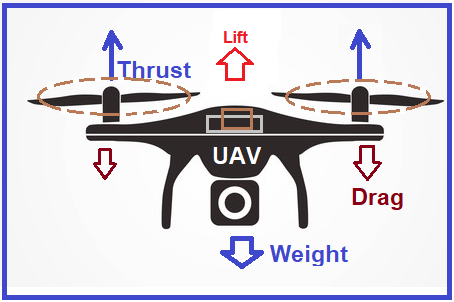

In their broadest form, Drone propellers are known to be the part that creates lift & thrusts in drones. On rotation by the motor that is on the drone, the propeller’s blade causes a pressure difference, hence providing the lift force. This gives the drone the ability to take off the ground, remain steady or even fly in a given direction.

They include the size and shape of the propeller, the material used, and the number of blades in the propeller. If these factors are well tuned the propeller complements the other systems of the drones to produce smooth flights that are easy to control.

MEPSKING engineers have done a great job of propellers considering the differences between racing drones and industrial surveying drones.

Propeller Efficiency Concerns and Its Relationship with Key Parameters

1. Blade Pitch

The positioning of a propeller is the evaluation of the blades in relation to the direction in which they are spinning through the air. A higher pitch implies that the blades are more inclined, therefore creating more force, although the need for power to be supplied by the motor increases as well. Low pitch propellers on the other hand produce less force but they are useful when one requires slow and constant revolutions.

2. Number of Blades

The number of blades on a propeller relates to both the power and efficiency of the propeller in question. The most popular type of propeller is the two-blade propeller, which is used in most drones, and delivers adequate thrust at relatively low energy consumption. However, that means more blades, which will provide more thrust, and make the drone more reactive to the pilot’s movements. This comes with a higher cost of energy put into use, as well as reduced battery life in the devices.

MEPSKINGprovides both two-blade and multi-blade propellers based on the functionality of the UAV. In racing drones type where high thrust and rapid maneuverability are needed propellers of three or four blades are used. While the two-blade designs are used for flights lasting slightly longer time and with less power requirement, they are preferred.

3. Material Composition

The material used in making propellers influences the aspects of the durability of the propeller, its weight it, and the efficiency of the propeller. Some of the standard materials used are plastic, nylon carbon fiber, and composite ones. Plastic and nylon are cheaper in price compared to carbon fiber propellers, but they are not as strong since they can break under much less stress as compared to carbon fiber propellers which are strong, light in weight, and can withstand much more stress.

Some of the features of MEPSKING propellers include the use of high-grade carbon fiber in many of its propellers and strength enhanced through the use of high-grade carbon fiber without compromising on weight. It is particularly important for industrial types of UAVs that have to operate in wind, rain, and other adverse conditions, or at high altitudes.

4. Propeller Size

The diameter of a propeller also influences the flight of a drone in a particular manner as will be discussed in the following sections. Propellers with larger diameters work better as they produce more thrust which is necessary when it comes to drones used for lifting or transporting things such as cargo or heavy load instruments such as cameras and sensors among others. On the other hand, propellers of a comparatively smaller diameter offer more control and quicker rotation which is rather helpful for applications such as drone racing.

MEPSKING also provides various propellers with different sizes where the small ones are suitable for maneuvers and high-speed flight while the larger ones would support high payload and stable flight.

Types of Drone Propellers from MEPSKING

The propellers offered by MEPSKING include a large range to cover as many needs as possible in the drone community. Let’s explore the key types offered by MEPSKING: Let’s explore the key types offered by MEPSKING:

1. Racing Drone Propellers

Racing drones require high speed and maneuverability therefore they incorporate these two aspects in their design. MEPSKINGracing Drone propellers enable quick acceleration and maximum thrust to reach high velocity to maneuver fast while drones are making turns. These propellers are made of light yet strong materials such as carbon fibers so that they can be able to withstand the rigors of drone racing.

2. Heavy-Lift Propellers

The unmanned aerial vehicles that are used in delivering loads like cameras, sensors, and packages are usually equipped with high-capacity propellers to facilitate high levels of lift. MEPSKING heavy-lift propellers are greater in diameter and come with blade designs that are proactively designed for stability and efficiency. These propellers are primarily employed in sectors such as agriculture, construction, and logistics in applications including payload carrying and extended endurance operations.

3. Stealth Propellers

This is one of the product lines MEPSKING has come up with; they are stealth propellers. These propellers are designed to produce low noise during operation and this is crucial in areas such as city and surveillance or monitoring of wildlife where any form of noise is destructive. MEPSKING does this through the shape of the blades and the use of better materials so that drones may fly silently but with efficiency.

4. All-Weather Propellers

MEPSKING all-weather propellers appear able to produce efficient results in such circumstances as storms or heavy rain and sometimes even sleet. These propellers are constructed from highly wear-resisting materials that cannot corrode and be subjected to mechanical failure under any circumstances.

This makes them perfect for drones which are to be used in operations such as in disaster response, search and rescue, or environmental surveillance, which are bound to be prone to changes in weather conditions.

MEPSKING innovation in the propeller of drone

Propellers are not just a commodity that can be sourced from any other supplier; MEPSKING is the industry leader in propellers. This focus has also been manifested in the development of several key technologies that define their propellers hence making them a force to reckon with.

1. Aerodynamic Efficiency

MEPSKING has incorporated aerodynamics into the propellers it uses. By properly adjusting for the contours of the blade, its angles, and the quantity of such a blade, they can manage to minimize drag while at the same time maximizing lift. This enhances flight performance and battery utilization ultimately leading to longer flight durations, and hence, more challenging missions on a single charge.

2. Noise Reduction

Reminded a little earlier, MEPSKING propellers are stealthy and developed to be quiet. This is done by what is called ‘blade tip design’ whereby engineers ensure that there are no vortices that are normal to be formed during flight and which cause the noise. This technology should be best suited for sensitive applications where sound is a problem such as in the movie business, research on wildlife, or in areas where drones are used in urban centers.

3. Durability and Longevity

As mentioned earlier, the propellers used by MEPSKING are some of the hardest in the market today currently. To make a strong body structure, MEPSKING employs industrial carbon fiber together with other high-quality composites to ensure that the propellers of their drones are strong enough to withstand constant flights. This durability also increases the lifetime of the propellers and thus decreases the costs of operations so high for drone operators in the long run.

Drones Propeller- An Analysis of Their Prospects

Thus, it can be concluded that as the drone industry evolves, the market of required propellers will expand as well. Self-flying cars, aerial vehicles, and even the drone delivery systems that are going to be in use will need heavy-duty, efficient, and versatile propellers.

MEPSKING is already looking to incorporate these future requirements, such as intelligent propellers that can change their pitch angle while flying, for improved flying under various circumstances.

Conclusion

Propellers are arguably one of the most easily disregarded elements of a given drone but they are undoubtedly one of the most critical elements of that drone. MEPSKING has also remained committed to quality, innovation, and the needs of the customer in the manufacture of some of the most modern propellers in the market. Ranging from racing and leisure drones, and industrial use UAVs to special operations in more difficult conditions, MEPSKING propellers offer the quality, efficiency, and durability that enthusiasts fear not to find at their drone part suppliers.

With the evolution yet to be determined, MEPSKING is set to stick with the major propeller pioneer manufacturer and global exporter as the market is advanced with new propeller systems and solutions.