In order to survive in the current faced paced manufacturing world, manufacturers need to shift their attention from providing high quality products to optimizing production capacities. It means that the crucial competitive advantage that determines whether your company will succeed or fail can be in your ability to leverage fabrication capacity, no matter what business you are in – consumer goods, aerospace or automotive. This blog post explains why production capacity is important and how manufacturers can enhance it to meet increasing demands.

What is Production Capacity?

Production capacity can refer to the capability of manufacturing plant to produce their maximum output within normal conditions. This does not only involve the quantity of output but also the quality and consistency aspects. High levels of production capacities make it possible for companies to efficiently satisfy customer needs thereby reducing lead time and resultant costs which are very significant for remaining relevant in global markets.

Fabrication capacity as part of production capacity deals with creating parts or components through processes like machining, welding, and molding among others. Efficient utilization of fabrication capacity guarantees that each part will be produced as per specification, within time and at minimum total cost.

Strategies for Enhancing Production Capacity

Invest in Advanced Technology

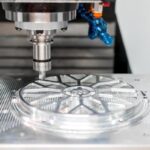

The investment in advanced machines and automation helps increase production capacities by a large margin. CNC machining, robotic welding, automated assembly lines among other technologies have quickened the pace of work while increasing accuracy and minimizing defects. Further still IoT devices once integrated into these machines facilitate gathering information about machine performance on real-time basis assisting predictive maintenance as well as breakdowns downtime reduction.

Optimize Workflow and Layout

This physical design matters because how work is arranged within a factory has a massive bearing on its total productive capacity. Manufacturers can reduce bottlenecks while improving efficiency by organizing workplaces logically thereby ensuring materials do not have distance travelled reduced. There are lean manufacturing principles such 5S (Sort, Set, Shine Standardize Sustain) which if implemented further streamline operations hence maximize on fabrication capacities.

Enhance Workforce Training

To optimize production capacity, a company must have well-trained employees. This regular training ensures that workers are knowledgeable about the latest technologies and processes to enable them to operate machines efficiently and identify problems quickly. Additionally, exposing employees to multiple roles is also important in developing flexibility for manufacturers without compromising the output as they need to respond to market fluctuation demands.

Implement Flexible Manufacturing Systems

Manufacturers should be capable of reacting promptly to shifting demand or production requirements hence flexibility in manufacturing process. Application of flexible manufacturing systems (FMS) enables companies produce different products with minimal downtime. Increased productivity levels and improved responding system to market changes come from said adaptability.

Focus on Preventative Maintenance

Production capacity can be hampered by unplanned downtime which remains a top threat. Well designed preventative maintenance programs keep equipment running at their best thereby avoiding costly breakdowns. Inspections done regularly, timely repair works carried out and predictive analytics employed in identifying possible areas of disruptions before they actually happen.

Conclusion

Maximizing production capacity is an ongoing effort involving investment in technology, workflow optimization, and employee training. Manufacturers are growing their fabricating capacity to satisfy increasing customer needs, minimize operating costs, and ultimately retain competitive advantage within the industry. As the industry moves forward those with higher priority based on production capacity will have a better chance of success over the long run.