Have you ever thought about how companies can make complicated metal shapes so quickly and accurately? Laser metal cutting is where the answer is. The way producers work is changing because of this tech.

It makes it possible to be very accurate and work quickly. Reading this blog post will teach you how laser metal cutting is changing the business world. You’ll learn what it can do for you and why it’s a game changer.

What is Laser Metal Cutting?

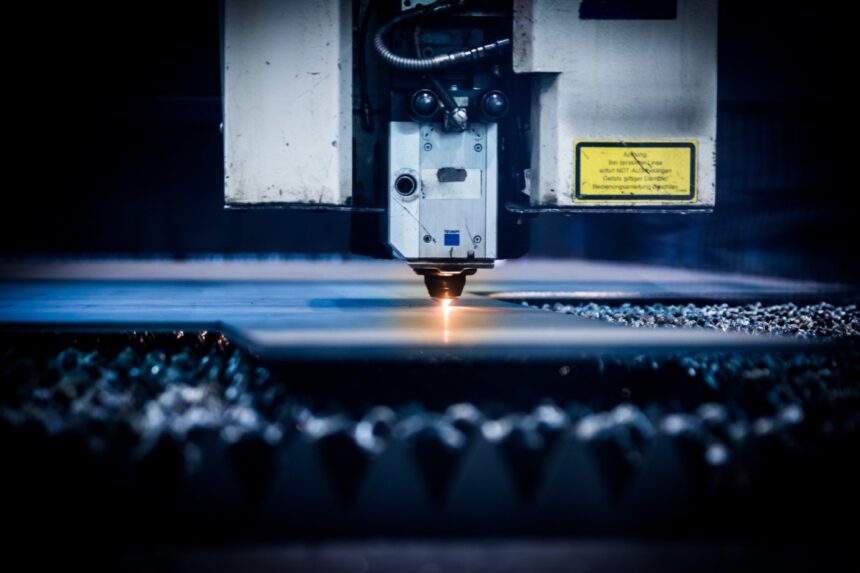

Laser metal cutting uses focused light to cut through metal materials. This method applies a high-power laser to slice through thick sheets with ease. It works by melting or burning the metal at high temperatures.

Businesses can use it for various metals, including steel and aluminum. Unlike traditional methods, it offers cleaner cuts and reduces waste. It’s a simple yet effective technique that many industries are now embracing.

Advantages of CNC Laser Cutting

CNC laser cutting is computer-controlled, which means it can perfectly follow patterns. One big benefit is speed; it works a lot faster than cutting by hand.

It can also easily work with complicated forms, which means you don’t have to do as much finishing work. It also cuts down on mistakes, which saves companies time and money. It works well and quickly to cut metal with this process.

Common Applications in Various Industries

Laser cutting is used in many industries today. Companies in automotive rely on laser cut sheet metal for parts. The aerospace sector uses this technology for complex designs.

Manufacturing creates everything from machinery to art pieces using laser cut aluminum. Even construction benefits from this method for structural components. The versatile applications showcase its importance in modern manufacturing.

Quality and Precision of Cuts

The quality of laser metal cutting is one of the best things about it. Since the cuts are smooth, they don’t need to be polished or shaped as much, which saves time. In many situations, accuracy is very important, and a laser cutter does a great job of it.

It’s easy to meet small tolerances, which leads to better goods. Manufacturers can depend on this technology to meet their needs because it gives them consistent results.

Sustainability and Cost-Effectiveness

Laser metal cutting is a sustainable option for many businesses. It generates less scrap material compared to traditional options. This means less waste for the environment.

Additionally, speed and efficiency mean lower operational costs. Over time, the savings can be significant. Companies can reduce their carbon footprint while enjoying savings, making it a smart choice.

Grafoil Laser Cutting: A Specialized Technique

Grafoil laser cutting is a specialized method that utilizes laser technology to cut flexible graphite materials. This technique offers unique advantages in industries requiring flexible materials, ensuring precision and high customization.

It complements traditional laser cutting, expanding material options. The adaptability of grafoil cutting showcases the versatility of laser technology, highlighting the ongoing evolution of laser metal cutting.

The Future of Laser Metal Cutting

In conclusion, laser metal cutting is revolutionizing the manufacturing industry. Its advantages in speed, precision, and cost-effectiveness are undeniable.

As businesses adopt this technology, they enhance product quality and sustainability. The future looks bright for laser metal cutting, and it will only keep growing.

Did you like this guide? Great! Browse our website for more!