Microfluidic technology has transformed the way we manipulate tiny volumes of fluids, leading to significant advancements in fields like biotechnology, pharmaceuticals, and diagnostics. By leveraging precise control over fluid flow at the microscale, researchers have been able to innovate processes that were once thought impossible. However, traditional microfluidic methods come with their own set of challenges—limitations that can hinder efficiency and scalability.

This is where a groundbreaking approach enters the scene: acoustofluidics. Imagine harnessing sound waves to drive fluid movement and achieve remarkable control over microenvironments. This cutting-edge technology opens up exciting possibilities for applications ranging from medical diagnostics to environmental monitoring. Let’s dive into this new paradigm in microfluidic technology and explore how acoustofluidics is reshaping our understanding of fluid dynamics on a microscopic scale.

Limitations of traditional microfluidic methods

Traditional microfluidic methods have revolutionized many fields, but they are not without their drawbacks. One significant limitation is the complexity involved in fabricating microchannels and devices. This often requires expensive materials and intricate manufacturing processes.

Another challenge lies in the control of fluid flow. In conventional systems, achieving precise manipulation can be cumbersome. Small variations may lead to significant discrepancies in results.

Additionally, traditional techniques struggle with scalability. Many methods work well on a small scale but falter when applied to larger volumes or higher throughput needs.

Moreover, these systems frequently depend on external pumps and valves for operation, which adds to their bulkiness and limits portability. Such dependencies can also introduce variability into experiments due to mechanical failures or inconsistencies over time.

These limitations underscore the need for innovative solutions like acoustofluidic technology that promise enhanced efficiency and flexibility in fluid management.

What is acoustofluidic technology?

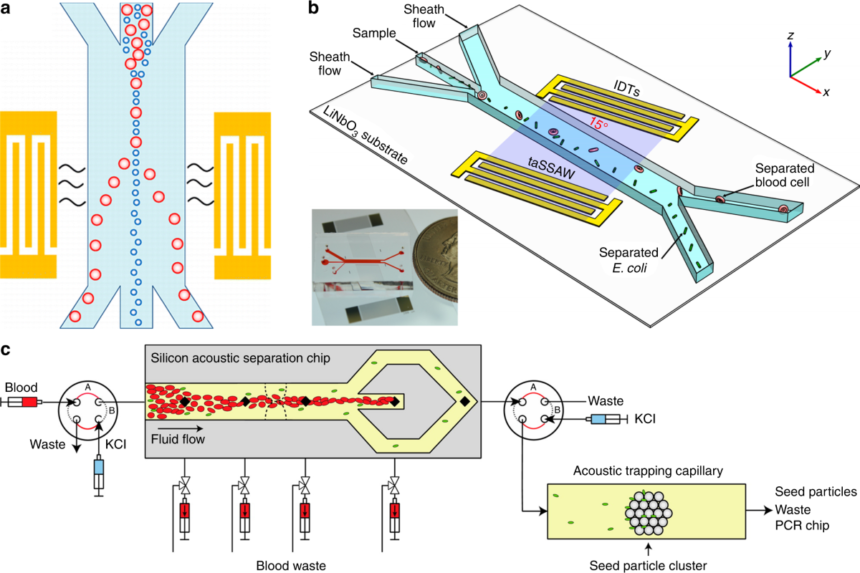

Acoustofluidic technology merges acoustics and fluid dynamics to manipulate small volumes of liquids. By leveraging sound waves, it creates unique opportunities for controlling the flow and behavior of fluids.

The core principle lies in using ultrasonic waves to generate acoustic fields. These fields exert forces on particles or droplets suspended within a fluid medium. This allows for precise positioning, sorting, and mixing without the need for mechanical components.

Unlike traditional methods that rely on pumps or valves, acoustofluidics offers a contactless approach. This reduces contamination risks while enhancing efficiency in various applications.

This innovative technology has gained traction across several sectors, including biotechnology, chemical analysis, and even drug delivery systems. Its ability to operate at microscale levels opens up new avenues for research and industrial processes alike.

How does acoustofluidic technology work?

Acoustofluidic technology harnesses the power of sound waves to manipulate fluids at a micro scale. It utilizes high-frequency acoustic fields to create pressure variations within a fluid medium.

These sound waves generate standing wave patterns, which can trap and move particles or droplets with remarkable precision. This process is known as acoustic trapping.

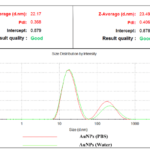

When the device emits ultrasound, it creates nodes and antinodes in the fluid. Particles tend to gather at these stable points, allowing for selective sorting or separation based on size, density, or other properties.

Additionally, acoustofluidics facilitates mixing by inducing flow patterns that enhance interactions between different components without needing mechanical pumps or valves. This leads to more efficient reactions in biochemical processes.

The versatility of this technology makes it suitable for a variety of applications ranging from diagnostics to drug delivery systems.

Applications of acoustofluidics in various fields

Acoustofluidics is making significant strides across multiple domains. In the biomedical field, it aids in cell sorting and manipulation with remarkable precision. This technique enhances drug delivery systems by ensuring targeted treatment delivery.

In environmental science, acoustofluidic devices are used for water quality monitoring. They can detect contaminants at minute concentrations, providing real-time data that helps maintain safety standards.

The food industry benefits too. Acoustofluidics helps in emulsification and mixing processes without altering the nutritional value of products. It improves efficiency while maintaining quality.

Moreover, this technology finds applications in microelectronics for precise assembly and testing of tiny components. Its versatility makes it a game-changer across various sectors, driving innovation forward as industries adapt to emerging challenges.

Advantages and future potential of acoustofluidic technology

Acoustofluidic technology presents a multitude of advantages that set it apart from traditional methods. One major benefit is its ability to manipulate small volumes of fluids with exceptional precision. This capability opens doors for more efficient chemical reactions and biological analyses.

Moreover, acoustofluidics minimizes sample contamination risks since it often requires less physical interaction with the samples themselves. The non-invasive nature allows researchers to monitor processes in real-time without altering the system.

Looking ahead, the potential applications are vast. Industries ranging from pharmaceuticals to environmental monitoring could see significant advancements through this technology. As research continues, innovations may lead to greater customization and scalability in acoustofluidic devices.

The integration of machine learning algorithms could further enhance performance by optimizing fluid dynamics on-the-fly. Such developments promise not only improved efficacy but also cost reductions in various sectors reliant on microfluidics.

Challenges and limitations of implementing acoustofluidics

Implementing acoustofluidics presents several challenges that researchers must navigate. One significant hurdle is the precise control of acoustic fields. Variations in fluid properties can affect wave propagation, leading to inconsistent results.

Additionally, scaling up from laboratory settings to commercial applications poses difficulties. The technology requires meticulous calibration and integration into existing systems, which can be time-consuming and costly.

Another limitation lies in material compatibility. Not all materials used in microfluidic devices are suitable for high-frequency ultrasonic waves. This restriction can limit design options and hinder broader adoption.

Moreover, while acoustofluidics shows promise across various fields, regulatory hurdles remain a concern. Approval processes for new technologies often lag behind innovation timelines, delaying deployment in critical areas like healthcare or environmental monitoring.

Addressing these challenges will require collaborative efforts among scientists, engineers, and industry stakeholders to refine techniques and expand applicability.

Conclusion

Acoustofluidic technology marks a significant leap forward in the realm of microfluidics. By harnessing the power of sound waves, it overcomes many limitations faced by traditional methods. The ability to manipulate fluids with high precision opens new avenues for research and industrial applications.

As we explore its advantages, such as reduced energy consumption and enhanced control over particle behavior, the potential becomes even more apparent. Fields like biotechnology, pharmaceuticals, and diagnostics are poised to benefit immensely from acoustofluidic innovations.

However, challenges remain in terms of scalability and integration into existing systems. Addressing these hurdles will be crucial for widespread adoption. As researchers continue to push boundaries in this field, acoustofluidic technology stands at the forefront of transformation within microfluidics.

By embracing this new paradigm, industries can expect not only improved efficiency but also groundbreaking advancements that were once thought impossible. The journey has just begun; there’s much more to discover on this exciting path ahead.