In industrial operations where downtime translates directly to lost revenue, the reliability of power systems isn’t just important—it’s absolutely critical. From remote mining sites operating around the clock to large-scale construction projects with tight deadlines, businesses depend on engines that deliver consistent performance under the most demanding conditions. The Cummins QSK50 has established itself as a leading industrial diesel engine, trusted by operations worldwide for its exceptional power output and proven durability. This heavy-duty engine combines advanced engineering with robust construction, offering impressive fuel efficiency, extended service intervals, and the ability to perform reliably in extreme environments. Whether powering massive earthmoving equipment, generating electricity for remote facilities, or driving hydraulic systems in offshore applications, the QSK50 consistently demonstrates why it has become the engine of choice for industrial professionals. This article explores the specific features and capabilities that make the Cummins QSK50 ideally suited for industrial use, examining its performance characteristics, real-world applications, and the comprehensive support infrastructure that ensures maximum uptime for operations that simply cannot afford to stop.

Overview of the Cummins QSK50 Engine

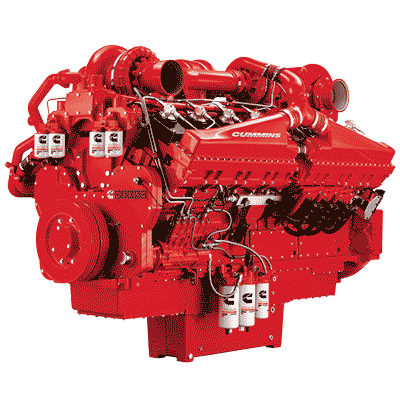

The Cummins QSK50 represents a pinnacle of heavy-duty diesel engine engineering, designed specifically to meet the rigorous demands of industrial applications. This V16 configuration engine features a displacement of 50 liters, delivering power outputs ranging from 1,400 to 2,000 horsepower depending on the specific rating and application requirements. The engine’s architecture incorporates a four-stroke cycle design with advanced fuel injection technology, ensuring optimal combustion efficiency across varying load conditions. Peak torque reaches an impressive 7,924 Nm, providing the substantial pulling power necessary for heavy equipment and demanding industrial processes.

Built with durability as a foundational principle, the QSK50 utilizes high-strength cast iron components throughout its block and cylinder heads, engineered to withstand extreme operating pressures and temperatures. The engine incorporates Cummins’ proven inline six-cylinder architecture multiplied across two banks, creating a robust platform that maintains structural integrity even during prolonged operation at maximum capacity. Advanced cooling systems and oil management technologies work together to protect critical components, while the modular design facilitates straightforward maintenance access. This combination of raw power and engineered resilience has made the QSK50 a trusted choice for operations where engine failure could result in catastrophic production delays, with many units accumulating tens of thousands of operating hours while maintaining consistent performance levels that justify the investment for industrial operators worldwide.

Performance and Efficiency of the QSK50

The Cummins QSK50 achieves remarkable fuel efficiency for an engine of its size, consuming approximately 195-210 grams of fuel per kilowatt-hour under optimal operating conditions. This efficiency stems from advanced common rail fuel injection systems that deliver precise fuel metering at pressures exceeding 2,000 bar, ensuring complete combustion while minimizing waste. The engine meets stringent emissions standards including EPA Tier 3 and EU Stage IIIA requirements through sophisticated exhaust gas recirculation and aftertreatment systems, allowing operations to maintain environmental compliance without sacrificing performance. In practical terms, this translates to lower operational costs over the engine’s lifespan, with fuel savings that can reach tens of thousands of dollars annually in high-utilization applications.

The QSK50’s power-to-weight ratio stands out among industrial diesel engines, delivering approximately 2.5 horsepower per kilogram of engine weight. This exceptional ratio means the engine maintains full power output even under sustained heavy loads, with minimal performance degradation during extended operation cycles. During comparative testing against competing 50-liter class engines, the QSK50 consistently demonstrates superior torque rise characteristics, providing up to 8% better low-end pulling power that proves invaluable when starting heavy equipment or managing variable loads. The engine’s electronic control systems continuously optimize injection timing, turbocharger boost pressure, and air-fuel ratios, adapting in real-time to changing operational demands. This intelligent performance management ensures the QSK50 operates at peak efficiency whether running at full capacity or partial loads, maintaining consistent output while extending component life through reduced thermal and mechanical stress during varying duty cycles.

Applications of the Cummins QSK50 in Industrial Settings

Mining operations represent one of the most demanding environments for the QSK50, where the engine powers ultra-class haul trucks, draglines, and rope shovels operating continuously in harsh conditions. At remote copper mines in Chile and coal operations in Australia, QSK50-powered equipment routinely operates 20-hour shifts, moving millions of tons of material annually. The engine’s ability to maintain full power output at high altitudes proves particularly valuable in mountainous mining regions, where atmospheric pressure reductions can diminish performance in lesser engines. One major iron ore operation reported that their QSK50-equipped haul trucks achieved 98.7% availability over a two-year period, significantly exceeding industry averages and demonstrating the engine’s reliability when maintenance protocols are properly followed.

In power generation applications, the QSK50 serves as the prime mover for generators producing 1.5 to 2 megawatts of electrical output, providing critical backup power for hospitals, data centers, and manufacturing facilities where electrical interruptions cause immediate operational and financial consequences. Offshore oil platforms in the North Sea utilize QSK50 generator sets as primary power sources, where the engine’s resistance to corrosive marine environments and ability to operate reliably during extended periods between maintenance windows proves essential. Construction projects benefit from the engine’s versatility, powering everything from large hydraulic excavators to concrete pumps and tunnel boring machines. A major infrastructure project in Southeast Asia deployed fifteen QSK50 engines across various equipment types, creating a standardized platform that simplified parts inventory, reduced technician training requirements, and enabled efficient maintenance scheduling across the entire fleet.

Custom configurations extend the QSK50’s capabilities to specialized industrial applications, with Cummins offering factory-engineered modifications for unique operational requirements. Marine propulsion variants incorporate modified cooling systems and marinized components for tugboats and workboats requiring sustained high-torque output. Oil and gas drilling operations utilize QSK50 engines configured for direct drive of mud pumps and drawworks, where the engine’s electronic governing systems maintain precise speed control critical for safe drilling operations. Cummins engineers work directly with equipment manufacturers to integrate the QSK50 into purpose-built machinery, optimizing mounting configurations, exhaust routing, and control system integration. These collaborative engineering efforts have resulted in successful deployments in applications ranging from mobile crushing plants processing aggregate materials to hydraulic power units driving pipeline construction equipment, demonstrating the engine’s adaptability across the industrial spectrum while maintaining the core reliability characteristics that define the QSK50 platform.

Power Pack Solutions Featuring the QSK50

Power pack solutions integrate the QSK50 engine with complementary components into pre-engineered, compact systems that deliver complete operational functionality in a single package. These turnkey configurations typically combine the engine with hydraulic pumps, cooling systems, fuel tanks, control panels, and mounting frames, all factory-tested and certified before shipment. This integrated approach eliminates the complexity of sourcing individual components from multiple suppliers, reducing procurement time from months to weeks while ensuring all elements work harmoniously together. Industrial operators benefit from simplified installation processes, as power packs arrive ready for connection to existing equipment with minimal on-site assembly required, dramatically reducing deployment costs and accelerating project timelines.

The QSK50’s modular design makes it particularly well-suited for power pack integration, with standardized mounting points and interface specifications that facilitate efficient packaging. Hydraulic power packs utilizing the QSK50 deliver flow rates exceeding 2,000 liters per minute at pressures up to 350 bar, providing the immense hydraulic force needed for heavy industrial machinery. A notable example involves a major tunneling project where QSK50-based hydraulic power packs drove tunnel boring machines through challenging geological formations, with the compact configuration allowing installation in restricted underground spaces while maintaining full serviceability. Marine power packs featuring the QSK50 provide propulsion and auxiliary power for workboats, with integrated cooling systems designed specifically for saltwater environments and shock-mounted configurations that absorb vessel vibrations. Suppliers such as GRT collaborate with specialized integrators to develop custom power pack solutions, offering engineering support that optimizes component selection, thermal management, and control system integration, ensuring each configuration meets specific operational requirements while maintaining the reliability standards that define QSK50-powered systems across industrial applications worldwide.

Maintenance and Support for the QSK50

Cummins recommends a comprehensive maintenance schedule for the QSK50 that balances operational uptime with preventive care, typically involving oil and filter changes every 500 operating hours under standard conditions, with intervals adjustable based on fuel quality and environmental factors. Major service intervals occur at 2,000-hour marks, including valve adjustments, fuel system inspections, and turbocharger examinations, while comprehensive overhauls are generally scheduled between 15,000 and 20,000 hours depending on duty cycle severity. Following these protocols systematically prevents minor issues from escalating into catastrophic failures, with data from industrial fleets showing that disciplined maintenance adherence reduces unscheduled downtime by up to 75% compared to reactive maintenance approaches.

The global Cummins support network ensures parts availability and technical expertise reach even remote industrial sites, with distribution centers strategically positioned to deliver critical components within 24-48 hours to most locations worldwide. Authorized service centers employ factory-trained technicians equipped with specialized diagnostic tools that interface directly with the QSK50’s electronic control modules, enabling rapid troubleshooting and precise repairs. Industrial diesel engine suppliers like GRT also provide parts and technical support for QSK50 operators seeking additional service options. To maximize engine lifespan, operators should implement oil analysis programs that detect wear metals and contaminants early, maintain clean fuel through effective filtration systems, and ensure cooling systems operate within specified temperature ranges. Installing hour meters and electronic monitoring systems provides real-time performance data, allowing maintenance teams to identify developing issues before they impact operations, while keeping detailed service records enables predictive maintenance strategies that optimize component replacement timing and extend the QSK50’s operational life well beyond standard expectations.

The QSK50 as a Proven Industrial Power Solution

The Cummins QSK50 stands out as an exceptional choice for industrial applications through its combination of robust power delivery, proven reliability, and comprehensive support infrastructure. With power outputs reaching 2,000 horsepower, exceptional fuel efficiency for its class, and the ability to maintain consistent performance across demanding duty cycles, this engine addresses the critical requirements of operations where downtime directly impacts profitability. Its successful deployment across mining, construction, power generation, and specialized industrial applications demonstrates real-world versatility, while the availability of integrated power pack solutions simplifies procurement and installation for complex projects. The global Cummins service network ensures that parts and technical expertise remain accessible even in remote locations, providing the operational confidence that industrial managers require. For engineers and project planners evaluating power solutions for heavy-duty applications, the QSK50 represents more than just an engine—it offers a complete ecosystem of performance, support, and proven reliability. When your operation demands an engine that delivers consistent power under the most challenging conditions while maintaining long-term durability, the Cummins QSK50 deserves serious consideration as the foundation of your industrial power strategy.