Introduction

If you’ve ever wondered how your electronic devices work, you’re not alone. Inside many of these devices is something called a printed circuit board, or PCB. These boards help connect different parts of the device so they can work together. One type of PCB that is becoming very popular is the aluminum PCB. In this guide by ViasionPCB, we’ll explain what an aluminum PCB is, why it’s special, and how it’s used in different types of products. Whether you are just curious or want to learn for your job or hobby, this guide will help you understand the basics.

An aluminum PCB is a special kind of circuit board made using aluminum as the base material. Most regular PCBs use a material called fiberglass, but aluminum boards are better in some ways. Aluminum can carry heat away from parts that get hot, which helps electronic devices last longer and work better. That’s why companies like ViasionPCB use aluminum PCBs in products that need strong performance and durability.

What Makes Aluminum PCBs Different?

Most PCBs are made with a non-metal base like fiberglass, which doesn’t handle heat very well. In contrast, aluminum is a metal that spreads heat very quickly. This makes aluminum PCBs a better choice for devices that get hot during use, like LED lights or computer parts. By using aluminum instead of fiberglass, the PCB can stay cooler, which helps all the parts last longer.

ViasionPCB knows the importance of heat management in electronics. That’s why their aluminum PCBs are used in many high-performance products. These boards not only work well but are also very reliable. The metal base of the aluminum PCB adds strength to the board, making it more resistant to damage. Plus, aluminum is lightweight, which is good for making small, portable devices.

How Are Aluminum PCBs Made?

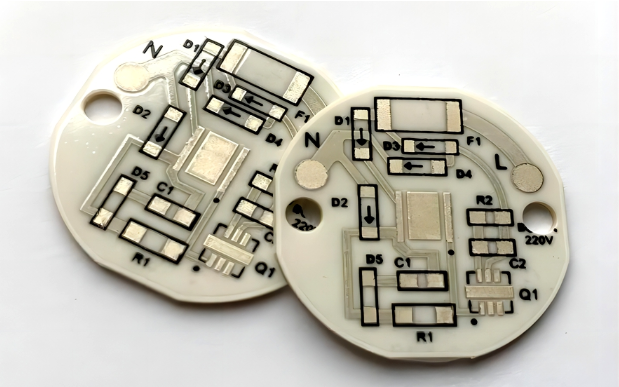

An aluminum PCB has several layers. The first layer is the aluminum base. On top of that is a thin layer of insulation that helps control heat and electricity. Then, a layer of copper is added, which carries the electric signals across the board. This copper layer is where all the parts get connected, like tiny roads for electricity to travel.

ViasionPCB follows a careful process to make sure every aluminum PCB meets high standards. They use strong insulation materials and quality copper to create boards that work well even in tough situations. The aluminum helps move the heat away from the hot parts, while the copper layer keeps the electrical signals flowing smoothly. This balance of materials makes these boards perfect for modern technology.

Where Are Aluminum PCBs Used?

You might not see aluminum PCBs every day, but they’re all around you. These boards are commonly used in devices that create a lot of heat. For example, LED lights often have aluminum PCBs inside. These lights can get hot, so they need help staying cool. Aluminum PCBs help keep the temperature down so the lights can last longer and shine brighter.

ViasionPCB supplies aluminum PCBs for many industries, including automotive, medical, and consumer electronics. Here are a few common uses:

- LED lighting systems

- Power supply equipment

- Motor control systems

- High-performance audio systems

- Solar power devices

All of these products benefit from the heat control and durability that aluminum PCBs provide.

Why Choose ViasionPCB for Aluminum PCBs?

Choosing the right company to make your aluminum PCBs is important. ViasionPCB is known for its high-quality products and great customer service. They use top materials, careful design, and expert workers to create boards that are reliable and affordable. Whether you need a small batch or a large order, ViasionPCB can help.

One reason why customers trust ViasionPCB is their experience. They have worked with clients from all over the world and understand many different needs. Their factory follows strict rules for quality, so every board is tested before it ships. This helps make sure that customers get aluminum PCBs that work the first time and keep working for a long time.

Advantages of Aluminum PCBs

Aluminum PCBs offer many benefits that make them better than traditional boards in certain cases. First, they are great at moving heat away from parts that get hot. This keeps the whole device cooler and safer. Second, aluminum PCBs are very strong, even though they are lightweight. This makes them ideal for devices that need to be both tough and portable.

Another big advantage is cost. Because aluminum is easy to find and work with, these PCBs are often more affordable than you might think. When you combine good performance, strength, and price, it’s easy to see why more companies are choosing aluminum PCBs made by ViasionPCB.

Challenges and Considerations

Even though aluminum PCBs are great, they’re not perfect for every situation. One challenge is that they can be harder to shape and cut than regular fiberglass boards. This means the design process needs to be very precise. Also, not every device needs the heat-handling power of aluminum, so sometimes a regular PCB is a better choice.

That’s why it’s important to work with a company like ViasionPCB. They can help you decide if an aluminum PCB is the right choice for your project. Their team knows how to handle these boards and can guide you through the whole process, from design to delivery.

Conclusion

Aluminum PCBs are changing the way electronic devices are built. Thanks to their ability to manage heat and provide strong support, these boards are becoming more common in today’s technology. Whether it’s LED lights, medical machines, or solar panels, aluminum PCBs offer reliable performance in demanding situations.

If you are thinking about using aluminum PCBs, ViasionPCB is a great place to start. With their quality products and expert support, they can help you get the best results for your project. Now that you understand what an aluminum PCB is and how it works, you’re ready to explore the world of electronics with confidence!