Introduction to the F1 Boiler Fault Code

The F1 boiler fault code is a well-known and critical error message read on many UK domestic boilers, most notably within brands like Ideal Logic and Glow-worm. This fault indicates that the boiler has detected dangerously low water pressure within the central heating system, a situation that jeopardizes safe operation. To prevent damage to essential heating components, the boiler automatically shuts down upon registering this code until the pressure level is restored to the manufacturer’s recommended safe range. Recognizing the causes and implications of the F1 code is vital for timely resolution and continued home comfort.

Root Causes of the F1 Fault: Why Does It Happen?

Low water pressure triggering the F1 fault arises from several common underlying issues. The most frequent cause is water leakage anywhere in the central heating system. Leaks may be obvious, such as visible drips or puddles near radiator valves, pipe joints, or boiler fittings. However, many leaks remain hidden within walls, under flooring, or behind radiators, requiring diagnostic skill to detect. Aging pipework often suffers corrosion, creating tiny fissures through which water escapes slowly, causing pressure to drop unnoticed over time. Additionally, trapped air in the heating circuits can interfere with water flow and pressure sensor readings, sometimes causing erroneous low-pressure indications. Sensor faults or poor calibration further complicate fault triggers, with pressure transmitters occasionally malfunctioning and signaling false low-pressure conditions.

Diagnosing and Troubleshooting F1 Faults at Home

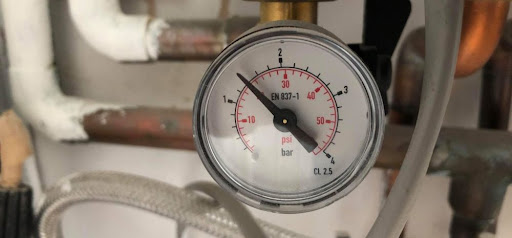

Homeowners confronting an F1 fault should initially confirm the system’s water pressure using the boiler’s pressure gauge, typically located on the front display panel or casing. When the boiler is cold, pressure levels should fall between roughly 1.0 and 1.5 bar, depending on manufacturer settings. If readings fall short, the water circuit requires repressurisation—commonly achieved through the boiler’s filling loop. This flexible metal braid equipped with valves connects the domestic mains water supply to the heating circuit. Opening the valves slowly admits water, increasing pressure to designated safe levels. After repressurisation, the boiler’s reset button clears the fault, restoring normal operation.

When You Should Contact a Professional

Recurrence of the F1 fault or inability to maintain system pressure signals deeper issues necessitating expert intervention. Certified Gas Safe-registered engineers offer comprehensive assessments capable of locating hidden leaks using ultrasonic or pressure testing tools. They can replace defective or aging pressure sensors, inspect and swap out the expansion vessel—a key component mitigating system pressure changes—and safely bleed radiators to expel trapped air. Professional repairs ensure full restoration of system integrity while safeguarding user safety.

Understanding the Expansion Vessel’s Role

The expansion vessel is a crucial element designed to handle pressure fluctuations as heating water expands and contracts. Its internal diaphragm separates the water and pressurised air sections. With age, diaphragm integrity degrades, reducing the vessel’s effectiveness and causing system pressure instability. Such failures manifest as repeated low-pressure faults despite repeated repressurisation attempts. Replacement is a specialist task, requiring system draining, component removal, and correct recharging.

Risks of Delayed Repair and Ignoring the F1 Fault

An unattended F1 fault risks boiler damage due to overheating of components like the heat exchanger or pump when running with insufficient water pressure. While the boiler shuts down to prevent severe damage, prolonged downtime affects home heating and hot water supply and may ultimately lead to costly replacement bills. Early recognition of related signs—cold radiators, unexplained water loss, or gurgling noises—is essential to intervene before extensive damage or energy waste occurs.

Preventative Maintenance Practices

Boiler longevity and fault prevention are closely tied to regular servicing. Annual professional inspection and maintenance maintain pipework seals, check valves and gauges, flush accumulated sludge, and verify expansion vessel condition. Homeowners should monitor boiler pressure monthly and familiarize themselves with repressurisation steps, performing them gently to maintain safe operating levels. Doing so reduces boiler wear and minimizes unscheduled breakdowns.

Conclusion: F1 Fault Code as the Boiler’s Crucial Safety Alert

The F1 fault code serves as a vital self-protection mechanism halting boiler operation under low water pressure conditions to prevent dangerous overheating and mechanical failures. While straightforward repressurisation solves many minor incidents, a profound understanding of the fault, its causes, and preventive actions empowers homeowners to sustain efficient, safe heating. Combining routine maintenance with timely professional support fortifies system health and preserves household comfort.