Corrugated plastic is a versatile material that is used in a wide range of industries due to its unique characteristics and durability. Made from plastic polymers, corrugated plastic is designed with a fluted structure similar to cardboard but made from durable plastic, making it resistant to water, chemicals, and extreme weather conditions. Its versatility and strength have made it an indispensable material in everything from signage to packaging, construction, and agriculture.

In this article, we will explore the features, types, benefits, common uses, and how corrugated plastic is revolutionizing industries worldwide.

What is Corrugated Plastic?

Corrugated plastic, often referred to by its brand name Coroplast, is a lightweight, yet durable material made from polypropylene or polyethylene. It is produced by sandwiching a layer of fluted plastic between two flat sheets, creating a honeycomb-like structure. This construction makes the material strong and resistant to bending and crushing while remaining lightweight and flexible.

Key Features of Corrugated Plastic:

-

Fluted Design: The corrugated structure, or fluting, gives the material its strength and rigidity, while also making it lightweight.

-

Weather-Resistant: Unlike paper-based corrugated cardboard, corrugated plastic is resistant to moisture, making it suitable for outdoor applications.

-

Recyclable: Made from polyethylene or polypropylene, corrugated plastic is 100% recyclable, making it an eco-friendly option.

-

Flexible and Impact-Resistant: Despite being light in weight, it is impact-resistant and can withstand moderate forces without breaking or deforming.

The fluted design not only enhances strength but also allows for ease of customization in terms of size, color, and printing options. These characteristics make it an ideal material for a variety of applications, both indoors and outdoors.

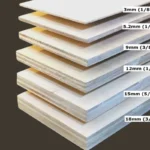

Types of Corrugated Plastic

Corrugated plastic comes in various grades, thicknesses, and colors, depending on the intended application. Understanding the different types of corrugated plastic can help you choose the best material for your project.

Single Wall Corrugated Plastic

Single-wall corrugated plastic consists of one layer of fluted plastic sandwiched between two smooth plastic sheets. It is the most common form of corrugated plastic and is typically used for signs, packaging, and temporary barriers.

Benefits:

-

Lightweight and easy to handle

-

Cost-effective

-

Available in various colors and sizes

Applications: Signage, point-of-sale displays, real estate signs, and temporary barriers.

Double Wall Corrugated Plastic

Double-wall corrugated plastic features two layers of fluted material, offering enhanced strength and rigidity. This type is thicker and more durable than single-wall corrugated plastic, making it suitable for more demanding applications.

Benefits:

-

Greater strength and rigidity

-

Better for heavy-duty use

-

More resistant to impacts and environmental conditions

Applications: Shipping containers, crates, protective covers, and construction materials.

Twin Wall Corrugated Plastic

Twin-wall corrugated plastic is similar to double-wall but with two outer smooth sheets and one inner layer of fluted material. This type is often used for applications requiring durability, but also where flexibility is important.

Benefits:

-

Lightweight yet durable

-

Can be used for both indoor and outdoor applications

-

Good insulator

Applications: Agricultural applications, insulation, and packaging.

Benefits of Corrugated Plastic

Corrugated plastic offers a wide range of benefits, making it a preferred choice in various industries. Here’s why this material is so widely used:

Durability and Longevity

One of the most significant advantages of corrugated plastic is its durability. Unlike traditional paper-based cardboard, corrugated plastic is resistant to water, chemicals, and UV rays, making it suitable for both indoor and outdoor applications. It can withstand harsh environmental conditions, including rain, snow, and intense sunlight.

Lightweight and Strong

Despite being lightweight, corrugated plastic is surprisingly strong. Its fluted design adds structure and strength without adding significant weight, making it easy to handle and transport. This balance between strength and lightness is one of the reasons it is so popular for signs, packaging, and construction materials.

Weather Resistance

Corrugated plastic is inherently resistant to weathering due to its water-resistant properties. It does not absorb moisture like cardboard, and it won’t warp or degrade when exposed to rain or humidity. This makes it perfect for outdoor signage, construction applications, and temporary structures that need to withstand the elements.

Cost-Effective

Corrugated plastic is often a more affordable option than many traditional materials such as wood, metal, or glass. It offers excellent performance at a fraction of the cost, making it ideal for businesses and individuals working within a budget.

Eco-Friendly

Made from recyclable plastic, corrugated plastic is an environmentally friendly choice. It is fully recyclable, which means it can be reused and repurposed. Using recycled corrugated plastic also helps reduce the environmental impact associated with plastic waste.

Versatile and Customizable

Corrugated plastic can be easily cut, shaped, and printed on, making it highly customizable for various uses. It can be manufactured in a variety of sizes, colors, and thicknesses, which makes it versatile for different applications. It can also be printed with high-quality graphics, making it perfect for branding and advertising purposes.

Common Uses of Corrugated Plastic

Due to its strength, versatility, and affordability, corrugated plastic is used across various industries. Here are some of the most common applications:

Signage and Displays

Corrugated plastic is commonly used in the creation of signs, advertisements, and point-of-sale displays. Its lightweight yet durable nature makes it ideal for both temporary and long-term use in commercial and retail environments. The ability to print high-quality images and text on corrugated plastic makes it a popular choice for marketing and promotions.

Applications:

-

Real estate signs

-

Yard signs

-

Billboard posters

-

Trade show displays

Packaging

Corrugated plastic is an excellent material for packaging due to its strength and lightweight properties. It can be used to create boxes, crates, and containers that are resistant to moisture, unlike cardboard packaging. Corrugated plastic packaging is often used for shipping delicate items and in industries such as automotive and electronics.

Applications:

-

Shipping boxes and containers

-

Storage crates

-

Custom packaging

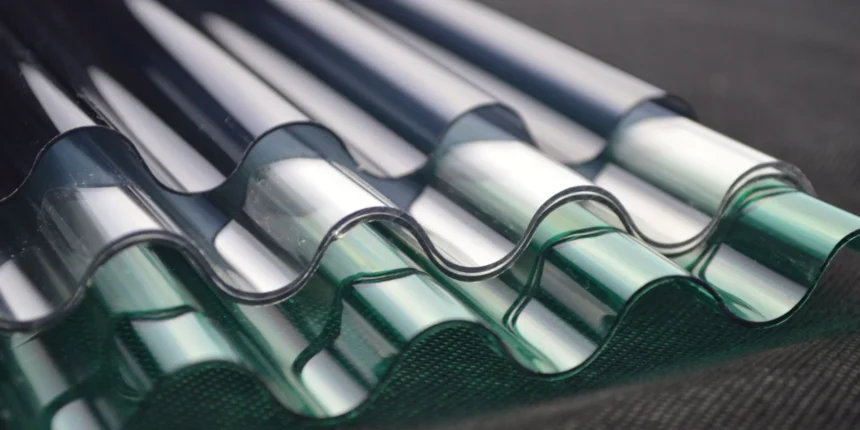

Construction and Building Materials

In the construction industry, corrugated plastic is used for both structural and non-structural applications. Its durability and resistance to moisture make it suitable for building materials like protective covers, temporary barriers, and outdoor shelters. It is also used for insulation and soundproofing in some construction projects.

Applications:

-

Temporary walls and dividers

-

Roofing panels

-

Protective covers for construction sites

Agricultural Use

Corrugated plastic is widely used in agriculture for various purposes, including irrigation systems, greenhouse covers, and protective panels for livestock. Its resistance to water, UV rays, and chemicals makes it ideal for these demanding environments. Additionally, its flexibility and ease of use make it a go-to material in farming applications.

Applications:

-

Greenhouse panels

-

Irrigation channels

-

Protective barriers for crops

Furniture and Interior Design

Corrugated plastic can also be used for innovative and modern furniture designs. Due to its flexibility, it can be shaped into creative forms for indoor furniture pieces, such as chairs, tables, and shelves. It can be combined with other materials or used on its own to create functional and eco-friendly designs.

Applications:

-

Modern furniture

-

Interior décor

-

Custom shelves and storage solutions

How to Work with Corrugated Plastic

Working with corrugated plastic is relatively easy, but there are some considerations to ensure that you get the best results for your projects. Here are some tips for working with this material:

Cutting Corrugated Plastic

To cut corrugated plastic, use a sharp utility knife or scissors. Make sure to cut along the flutes to avoid damaging the material. If a straight cut is needed, a ruler or cutting guide can help achieve a clean and precise line.

Drilling and Fastening

If you need to attach corrugated plastic to other materials, drilling small holes and using screws, nails, or rivets is an effective method. Be careful not to crack the plastic while fastening, and pre-drilling the holes may help prevent damage.

Printing on Corrugated Plastic

Printing on corrugated plastic is possible with high-quality UV printers or screen printing techniques. Ensure the surface is clean and free of dust or debris before printing to get the best results. You can also use adhesive vinyl for custom graphics and logos.

Conclusion

Corrugated plastic is a versatile, durable, and eco-friendly material that has transformed a wide range of industries. Its weather resistance, lightweight nature, and affordability make it ideal for everything from signage to packaging, construction, and agriculture. Whether you’re creating marketing materials, building structures, or designing furniture, corrugated plastic offers unmatched flexibility and functionality.

With its increasing popularity, understanding the features, types, and uses of corrugated plastic is essential for anyone looking to take advantage of this innovative material. From temporary signage to long-term applications, corrugated plastic continues to prove that it’s an indispensable material for various industries worldwide.