Designing custom metal parts can be a rewarding process, whether you’re an entrepreneur developing a new product, a hobbyist building a unique project, or an engineer tasked with improving an existing system. However, one challenge that almost everyone faces is controlling costs. Creating custom metal parts can become expensive if you’re not strategic with your design choices. The good news? There are proven ways to keep costs down without sacrificing quality.

Below, we break down some key tips for designing cost-effective custom metal parts, from material selection to design simplification and manufacturing considerations.

1. Choose the Right Material

Material selection is one of the first and most important decisions you’ll make. Different metals have different properties and different price tags.

- Use Standard Materials: Whenever possible, stick with standard grades of steel, aluminum, or other common metals. Exotic alloys or specialty materials can dramatically increase costs.

- Consider Material Availability: Select materials that are readily available in your area. Materials that need to be specially ordered, imported, or manufactured in non-standard sizes will add both cost and lead time.

- Balance Performance and Cost: Don’t over-specify. For example, if you need corrosion resistance, aluminum might be cheaper than stainless steel for your application.

Tip: Consult with your manufacturer or supplier early on to confirm the best material choice for your needs and budget.

2. Simplify Your Design

Complexity is expensive. The more complicated a part is, the more it will cost to make. Here’s how to simplify:

- Reduce the Number of Features: Eliminate unnecessary holes, slots, or decorative features unless they’re essential.

- Avoid Tight Tolerances: Specify tight tolerances (like +/- 0.01mm) only where absolutely necessary. Looser tolerances are faster and cheaper to achieve.

- Design for Manufacturability (DFM): Think about how your part will actually be made. Simple shapes, such as flat plates or basic bent profiles, are easier and cheaper to produce.

- Limit Secondary Operations: Minimize the need for processes like welding, threading, or surface finishing. Each additional operation adds to the cost.

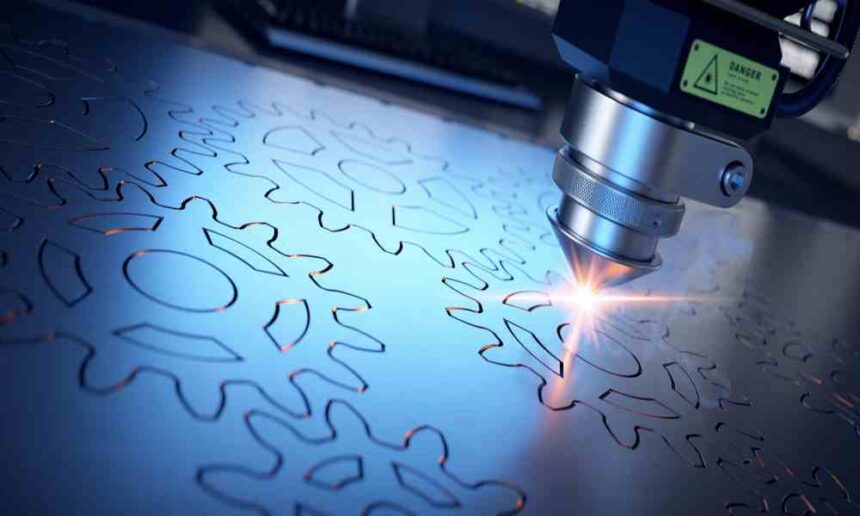

3. Optimize for the Manufacturing Process

The way your part is made cutting, bending, stamping, machining, or casting will greatly influence the cost. Optimize your design for the process you intend to use:

Sheet Metal Parts

- Keep Bends Simple: Bends should be in the same direction when possible. Each change in direction means an extra setup.

- Allow for Standard Bend Radii: Don’t specify custom bend radii unless it’s critical.

- Avoid Very Small Features: Small holes or notches may require special tooling.

Machined Parts

- Minimize Deep Cuts and Cavities: Deep features take longer to machine and may need specialized (and expensive) tools.

- Standardize Hole Sizes: Use standard drill sizes rather than custom dimensions.

- Design for Tool Access: Avoid features that are hard to reach or require custom tools.

Cast or Molded Parts

- Uniform Wall Thickness: Keeping the wall thickness consistent reduces defects and costs.

- Add Draft Angles: Slight tapers help with part removal and reduce tooling wear.

4. Use Standard Components and Features

Where possible, use standard fasteners, hinges, bushings, or other hardware. Customizing these elements adds cost and complexity to both manufacturing and assembly.

- Standard Thread Sizes: Design holes and fasteners to match commonly available screw and bolt sizes.

- Off-the-Shelf Parts: Incorporate widely available components to save on both cost and lead time.

5. Minimize Waste

Material waste translates directly to higher costs. Here’s how to minimize it:

- Nesting: Arrange multiple parts efficiently when cutting from a sheet or plate to get the most out of each piece.

- Standard Stock Sizes: Design parts to fit within standard material sizes, reducing offcuts.

- Avoid Unnecessarily Thick Sections: Thicker material costs more and may require extra machining.

6. Collaborate Early with Your Manufacturer

One of the best ways to design cost-effective parts is to involve your manufacturer early in the design process. They can:

- Advise on the best materials and processes for your needs.

- Suggest ways to simplify your design.

- Help identify potential production challenges before they become costly problems.

Many custom metal part manufacturers offer Design for Manufacturability (DFM) feedback. Don’t be afraid to ask for it!

7. Plan for Scalability

If you expect to scale up production later, design your parts with higher volumes in mind:

- Tooling Investment: Some methods (like stamping or casting) require expensive tooling, but per-part costs drop dramatically at higher volumes.

- Modular Design: Design parts that can be reused or adapted across different products to save on tooling and design costs.

- Batch Processing: Consolidate operations or combine parts where possible to reduce setup times.

8. Consider Surface Finish Requirements

Not all parts need a polished or coated finish. Surface finishing can add significant cost:

- Specify Only Where Needed: Only specify surface finishes where they matter functionally or aesthetically.

- Use As-Made Finishes: If a rough or unfinished look is acceptable, skip polishing, coating, or painting.

9. Design for Easy Assembly

Think about how your part will be assembled with other components:

- Self-Locating Features: Tabs, slots, or notches help align parts quickly and accurately.

- Minimize Fasteners: Fewer screws or bolts mean faster assembly and lower hardware costs.

- Plan for Automation: If you plan to automate assembly in the future, avoid designs that are difficult for machines to handle.

10. Prototype and Iterate

Finally, build a prototype before committing to large production runs. Prototyping helps identify design issues early, saving you money on costly rework later.

- Rapid Prototyping: Use 3D printing or CNC machining for quick, low-volume samples.

- Gather Feedback: Use your prototype to get feedback from stakeholders, end-users, and your manufacturer.

Conclusion

Designing cost-effective custom metal parts is all about making smart choices at every stage: from material selection and design simplification to collaborating with your manufacturer. By following the tips above, you’ll not only reduce your costs but also end up with better, more manufacturable parts, giving your project a solid foundation for success.

Remember: simple, standard, and scalable designs save time and money without compromising quality.