Rethinking Packaging Efficiency

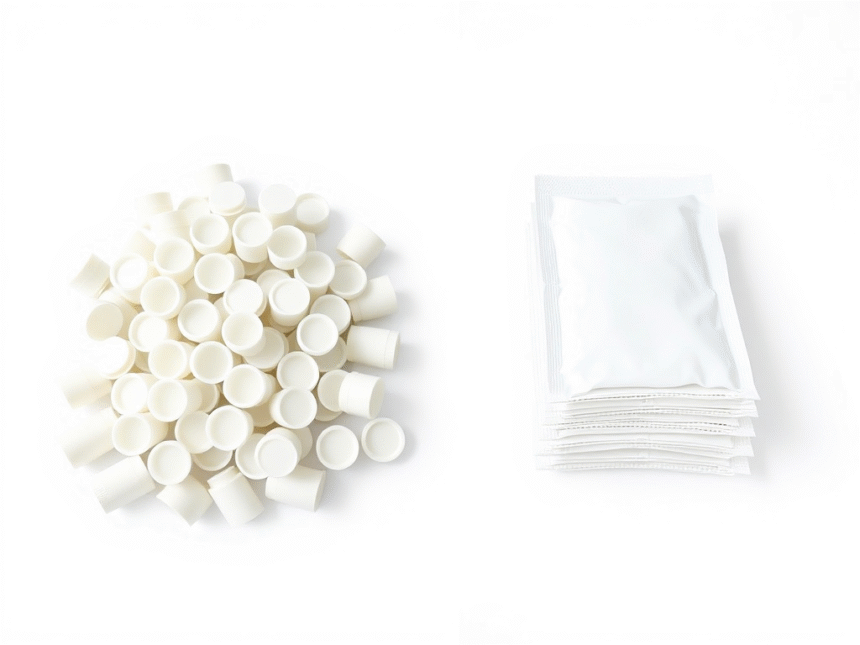

Modern supply chains are under pressure to reduce waste and cut costs without sacrificing performance. That’s where Lubepack comes in. By replacing rigid plastic tubes with flexible Tear ‘n’ Tuck packaging, it’s possible to reduce plastic usage by up to 70% and bring packaging expenses down by as much as 50%—a shift that’s gaining ground across sectors from manufacturing to retail.

These lightweight, easy-to-use packs are designed for single-use or controlled dispensing, depending on the application. Unlike traditional tubes, they don’t require hard plastic shells or bulky caps. That means lower material consumption, faster production, and better logistics—all wrapped up in a tidy, tamper-evident format.

Why Tear ‘n’ Tuck Cuts Costs and Carbon

One of the biggest advantages of Tear ‘n’ Tuck packaging is its efficiency throughout the entire supply chain. Because these packs are compact and flexible, they take up far less space in transit and storage. More units per pallet, fewer deliveries, and tighter shelf layouts all contribute to measurable cost savings.

Production savings are equally compelling. Traditional tubes often use layered plastics, inserts, and moulded components. Tear ‘n’ Tuck, on the other hand, relies on a simpler, flat-pack design with heat-sealed seams. That means lower manufacturing costs, reduced energy use, and minimal waste during production.

Practical Advantages in Day-to-Day Use

It’s not just manufacturers who benefit—end users do too. Tear ‘n’ Tuck packs are easy to open without scissors or extra tools, making them ideal for use in industrial settings, on-the-go kits, or even sample distribution. The flat design also makes them easier to store in tight spaces, such as toolboxes, drawers, or display stands.

Durability is built in. While flexible, the material and seals used in Tear ‘n’ Tuck packaging offer strong resistance to leaks and punctures. This makes them suitable for both high-viscosity lubricants and more fluid products, ensuring the contents are protected without adding unnecessary bulk.

Lower Waste, Higher Impact

Reducing environmental impact is no longer optional. Tear ‘n’ Tuck packaging makes it easier to meet sustainability targets by using significantly less plastic, creating less landfill waste, and reducing emissions linked to transport. It’s a practical, scalable way for businesses to make meaningful change without compromising usability or product quality.

The design also lends itself to recyclable materials and refillable formats, which can further extend the environmental benefits. For brands looking to make packaging part of their sustainability story, this is a simple yet effective place to start.