AI and precision engineering for sustainable manufacturing process by JS Precision

Introduction

Sustainable manufacturing is transforming industry practices by integrating AI-driven machining and precision engineering to significantly reduce waste and lower carbon emissions. Companies like JS Precision are leading this shift, using advanced CNC machining technologies to support eco-friendly production without compromising quality or efficiency.

In the pursuit of greener industrial practices, companies like JS Precision are at the forefront, integrating advanced AI with high-precision CNC machining to dramatically reduce material waste and energy consumption. By leveraging intelligent algorithms, real-time data, and ultra-accurate machining systems, manufacturers can now achieve eco-friendly machining that is faster, cleaner, and more efficient. This combination of AI-driven machining and precision engineering is not just enhancing productivity—it’s redefining what responsible and efficient manufacturing looks like.

AI-Driven Optimization: The AI Revolution on the Factory Floor

Artificial intelligence is transforming manufacturing by making production smarter and more sustainable. Through predictive maintenance, machines can detect potential failures before they happen, minimizing downtime and extending equipment life. Intelligent toolpath optimization further helps to reduce material waste and energy consumption, ensuring every cut and movement is efficient and precise.

At JS Precision, AI is deeply integrated into daily operations. For instance, the company’s proprietary software analyzes CAD models to calculate the most material-efficient cutting paths, a process that has helped clients like super tech autoparts ltd, reduce their aluminum waste by upto 15%. Combined with real-time quality control systems, this AI-driven approach not only enhances accuracy but also supports greener, leaner manufacturing—proving that smart technology can drive both sustainability and performance on the factory floor.

Closed-Loop Systems and Material Innovation ( Materials & Recycling)

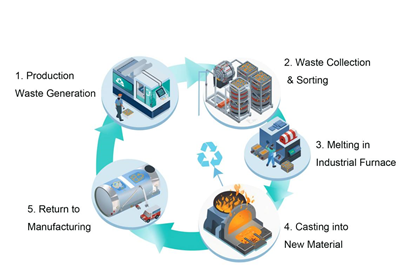

The closed-loop recycling system turns CNC machining waste back into valuable raw materials, creating a circular and sustainable manufacturing economy.

A key step toward sustainable manufacturing is building a closed-loop system—one where materials and resources are continually reused instead of wasted. Modern factories are adopting coolant recycling systems that clean and reuse cutting fluids, significantly reducing chemical waste and environmental impact. Likewise, metal scrap reuse programs ensure that valuable materials like aluminum and titanium are collected, remelted, and reintroduced into production rather than discarded.

The company like JS Precision actively promotes the use of recycled aluminum alloys and other eco-friendly materials in CNC machining projects. Combined with precise process control and digital monitoring, these innovations minimize raw material consumption while maintaining the highest quality standards. Through such green manufacturing solutions, JS Precision demonstrates how technology and responsibility can work hand in hand to close the loop on waste.

The Inherent Efficiency of Precision (The Inherent Efficiency of Precision)

Advanced 5-axis CNC machining enables ultra-tight tolerances and mirror finishes for critical aerospace applications.

In sustainable manufacturing, precision isn’t just a performance advantage—it’s an environmental one. High-precision CNC machining ensures parts are produced right the first time, minimizing costly rework, rejections, and wasted materials. Every micron of accuracy contributes to saving resources, energy, and time throughout the production cycle.

At JS Precision, advanced 5-axis CNC equipment and a digital quality monitoring system make this possible. By maintaining tolerances as tight as ±0.005mm, the company consistently delivers flawless components that meet strict aerospace and automotive standards. This “first-time-right” production approach eliminates unnecessary machining passes and scrap, demonstrating how precision engineering directly supports eco-friendly machining. Simply put, when manufacturing is more accurate, it’s naturally more sustainable—a perfect balance of performance and responsibility.

Case Study

A recent aerospace project highlights how JS Precision combines AI-driven machining with 5-axis CNC technology to achieve remarkable sustainability gains. The client needed a lightweight, high-strength structural component traditionally made from multiple parts. By leveraging advanced 5-axis machining, JS Precision successfully consolidated several components into a single precision-milled piece, eliminating the need for complex assembly and extra fasteners.

This innovation not only reduced assembly waste but also improved overall structural integrity and performance. Through precise machining paths and optimized material usage, the project achieved a significant cut in both material scrap and production time. Supported by JS Precision’s digital quality monitoring system, every step was validated for accuracy and efficiency—demonstrating how smart engineering and sustainability can go hand in hand in the most demanding industries like aerospace.

How to Start Your Sustainable Manufacturing Journey

Embarking on a sustainable manufacturing journey begins with making informed choices that balance performance with environmental responsibility. Start by partnering with suppliers who hold recognized certifications such as ISO 14001, which ensures systematic environmental management and continual improvement. Next, inquire about the recyclability and sourcing of materials—opt for recycled metals or eco-friendly alternatives whenever possible.

It’s also vital to collaborate with manufacturers who use AI-driven machining services and closed-loop systems, as these technologies minimize waste and energy use throughout production. At JS Precision, clients benefit from detailed Design for Manufacturability (DFM) feedback, helping them design smarter, more resource-efficient parts from the outset. By prioritizing partners who integrate sustainability into every step, manufacturers can achieve cost savings, regulatory compliance, and a stronger environmental reputation—all while advancing toward a greener future.

Conclusion & Call to Action

The path to sustainable manufacturing is being shaped by three powerful forces—AI-driven optimization, closed-loop material systems, and the inherent efficiency of precision engineering. Together, these trends are redefining how modern factories operate, producing cleaner, smarter, and more efficient results.

With its advanced 5-axis CNC technology, AI-optimized machining, and digital quality monitoring, JS Precision continues to lead this transformation. The company’s intelligent, eco-friendly approach proves that sustainability and high performance can go hand in hand.

Ready to make your manufacturing process more efficient and sustainable? JS Precision offers free DFM analysis and instant quotes to help you start your next project with precision and responsibility.