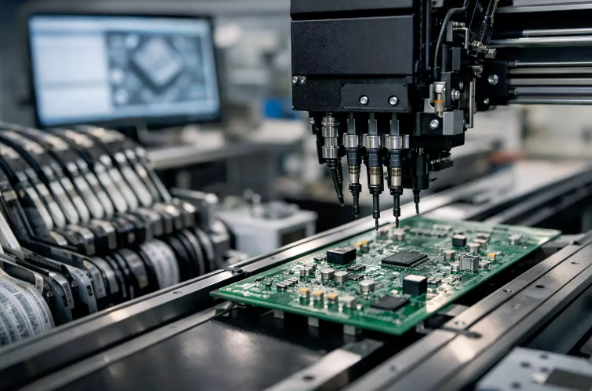

Modern electronic devices are becoming smaller, lighter, and more complex than ever before. From wearable gadgets and medical equipment to aerospace systems and consumer electronics, the demand for compact and highly reliable circuit boards is rapidly increasing. Two innovations that are playing a vital role in meeting these demands are rigid-flex pcb technology and FastTurn PCB manufacturing services. Together, they provide flexibility in design, durability in performance, and speed in production that traditional PCBs simply cannot match.

What is a Rigid-Flex PCB?

A Rigid-Flex PCB is a hybrid circuit board that combines both rigid and flexible board technologies into a single unit. It consists of multiple layers of flexible circuits attached to rigid boards, allowing the PCB to bend and fold while maintaining structural integrity. This design eliminates the need for connectors, cables, and solder joints that are typically used to connect separate rigid boards.

Rigid-Flex PCBs are widely used in industries where space, weight, and reliability are critical factors. These include:

- Medical devices such as pacemakers and diagnostic equipment

- Aerospace and defense electronics

- Smartphones, cameras, and wearable devices

- Automotive control systems

By integrating flexible and rigid sections into one board, engineers can design more compact devices with fewer connection points, which reduces the risk of failure.

Key Benefits of Rigid-Flex PCB

Space and Weight Reduction

Rigid-Flex PCBs allow designers to fold the circuit into three-dimensional shapes. This is ideal for compact products where every millimeter of space matters. Eliminating connectors and cables also significantly reduces weight.

Improved Reliability

Traditional PCB assemblies rely on connectors and wires, which are common points of failure. A Rigid-Flex PCB removes these weak points, leading to greater durability and longer product lifespan.

Better Signal Integrity

With fewer interconnections and shorter signal paths, Rigid-Flex PCBs offer improved electrical performance and reduced signal interference, which is essential for high-speed and high-frequency applications.

Enhanced Design Flexibility

Designers can create innovative layouts that would be impossible with standard rigid boards. This flexibility allows for more creative and efficient product designs.

Applications of Rigid-Flex PCB

Rigid-Flex PCBs are ideal for applications that require high performance in tight spaces. For example, in medical implants, the PCB must fit into a very small enclosure while remaining extremely reliable. In aerospace equipment, the board must withstand vibration, temperature changes, and mechanical stress. Rigid-Flex technology meets all these requirements effectively.

What is FastTurn PCB?

While advanced PCB designs like Rigid-Flex are important, speed is equally critical in today’s competitive market. This is where FastTurn PCB services come into play. FastTurn PCB refers to rapid PCB prototyping and manufacturing services that deliver high-quality boards in a very short time, often within 24 to 72 hours.

FastTurn PCB manufacturing is essential for:

- Rapid prototyping

- Product testing and development

- Urgent production requirements

- Time-sensitive projects

Companies developing new electronic products cannot afford to wait weeks for PCB fabrication. FastTurn services allow engineers to test, modify, and finalize their designs quickly.

Advantages of FastTurn PCB Services

Faster Product Development

FastTurn PCB services significantly reduce the time between design and testing. Engineers can receive prototypes quickly, identify issues, and make improvements without delays.

Reduced Time to Market

In competitive industries, being first to market is crucial. FastTurn PCB helps companies launch products faster by speeding up the development cycle.

High-Quality Prototyping

Despite the quick turnaround time, FastTurn PCB manufacturers maintain high standards of quality, ensuring that prototypes are reliable and accurate.

Cost Efficiency in Development

Faster prototyping means fewer delays and reduced development costs. Companies can iterate designs more efficiently without long waiting periods.

Combining Rigid-Flex PCB with FastTurn PCB

The true advantage comes when Rigid-Flex PCB technology is combined with FastTurn PCB manufacturing. Designers can create complex, space-saving PCB layouts and receive prototypes in record time. This combination is extremely beneficial for industries that require both advanced design and rapid development.

For example, a wearable device manufacturer can design a compact Rigid-Flex PCB that fits perfectly into a small enclosure and receive the prototype within days using FastTurn PCB services. This speeds up testing and ensures the product meets performance requirements before mass production.

Industries Benefiting from Rigid-Flex and FastTurn PCB

Several industries are leveraging these technologies:

- Medical Industry: Compact, reliable PCBs for life-saving equipment

- Aerospace and Defense: Lightweight and durable circuit boards for harsh environments

- Consumer Electronics: Slim and flexible designs for modern gadgets

- Automotive Sector: High-performance boards for control systems and sensors

- Telecommunications: Reliable boards for high-speed signal transmission

Choosing the Right PCB Manufacturer

When selecting a PCB manufacturer for Rigid-Flex PCB and FastTurn PCB services, it is important to consider:

- Experience with complex Rigid-Flex designs

- Advanced manufacturing equipment

- Strict quality control standards

- Ability to deliver within tight deadlines

- Technical support for design optimization

A reliable manufacturer ensures that both the design complexity and fast delivery requirements are handled without compromising quality.

Conclusion

As electronic devices continue to evolve, the need for smarter PCB solutions is growing. Rigid-Flex PCB technology offers unmatched design flexibility, durability, and space-saving benefits, while FastTurn PCB services provide the speed required for modern product development. Together, they form a powerful combination that enables innovation, reliability, and efficiency.

Businesses that adopt these advanced PCB solutions gain a competitive advantage by delivering high-performance products faster and more efficiently. Whether it is for medical devices, aerospace systems, or consumer electronics, Rigid-Flex PCB and FastTurn PCB are shaping the future of circuit board manufacturing.