Precision manufacturing is undergoing a remarkable transformation as industries embrace automation, digital technologies, and sustainable materials. Today’s manufacturers are moving beyond traditional methods to adopt smarter, faster, and more efficient production systems. Automated CNC machining, AI-driven quality control, and advanced robotics are revolutionizing how parts are designed and produced, ensuring exceptional accuracy and repeatability. At the same time, the growing focus on sustainability is pushing manufacturers to explore eco-friendly materials and energy-efficient processes. This combination of innovation and responsibility is shaping a new era where speed, precision, and environmental care go hand in hand. In this evolving landscape, forward-thinking companies like LS Manufacturing are leading the way — blending cutting-edge CNC machining services with rapid prototyping & injection molding to meet global demand for high-quality, precision-engineered components.

Figure 1: The 4 Key Trends Reshaping Precision Manufacturing in 2024. Share this graphic to help your network stay informed. [Picture Source: LS Manufacturing]

Key Trends in 2024

1. Advanced 5-Axis CNC Machining

This technology allows for the production of complex parts with exceptional accuracy and fewer setups. This capability not only reduces production time but also enhances surface quality, making it ideal for demanding applications in the aerospace, automotive, and medical industries.

2. Rapid Prototyping & Digital Fabrication

The adoption of 3D printing and digital fabrication enables engineers to test designs quickly and cost-effectively before committing to full-scale production. This approach significantly speeds up innovation and helps companies bring products to market faster.

3. Automation & Smart Manufacturing

Intelligent systems are driving progress across the production floor. From AI-powered quality checks to automated toolpaths, this trend is focused on improving efficiency and consistency while minimizing human error.

4. Sustainability & Waste Reduction

A growing focus on eco-friendly materials and energy-efficient processes reflects a broader industry commitment to sustainable production. Manufacturers are increasingly adopting practices that reduce environmental impact without compromising on quality.

Together, these trends define the modern era of precision manufacturing, combining cutting-edge technology with a responsible approach to production.

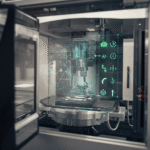

Figure 2: Diagram of 5-Axis CNC machining capabilities, allowing for the production of complex geometries in a single setup.

Case Study

A great example of innovation in precision manufacturing comes from LS Manufacturing, a trusted provider of high-quality CNC machining services. Recently, the company partnered with a leading automotive manufacturer to produce complex aluminum components requiring exceptional precision and tight tolerances. Using advanced 5-axis CNC machining and digital quality control systems, LS Manufacturing was able to deliver parts with accuracy up to ±0.005mm — exceeding industry standards.

What truly set LS Manufacturing apart was its ability to combine speed with reliability. Through its rapid prototyping & streamlined production workflow, the team reduced the customer’s development time by nearly 40%, allowing faster testing and market launch. Every stage, from material selection to final inspection, was carefully monitored to ensure consistent quality.

This project highlights how LS Manufacturing’s expertise, commitment to excellence, and customer-focused service make it a leading name in precision manufacturing — providing innovative solutions for industries that demand the highest standards.

Figure 3: A precision-machined automotive component produced by LS Manufacturing, showcasing the exceptional surface finish and dimensional accuracy achieved for our clients in the automotive industry.

Why Choose LS Manufacturing

Choosing the right precision manufacturing partner can make all the difference — and LS Manufacturing stands out for its unmatched quality, speed, and reliability. The company operates under ISO 9001, IATF 16949, and AS9100D-certified quality standards, ensuring every part meets stringent inspection and performance requirements. From aerospace to automotive industries, LS Manufacturing delivers precision components that consistently exceed expectations.

One of its biggest advantages is fast delivery. With advanced production systems and efficient workflow management, LS Manufacturing can deliver prototypes and production parts in as little as a few days. This rapid turnaround helps clients reduce project timelines and respond quickly to market demands.

Additionally, the company’s use of cutting-edge CNC machining technology, combined with expertise in injection molding and rapid prototyping, ensures accuracy and flexibility for both small and large-scale projects. When quality, speed, and reliability matter, LS Manufacturing is the trusted choice for precision-engineered solutions.

Conclusion

The precision manufacturing industry is rapidly evolving, driven by automation, digital innovation, and a growing focus on sustainability. From 5-axis CNC machining to rapid prototyping, these trends are reshaping how products are designed and produced across industries. In this dynamic landscape, LS Manufacturing continues to lead the way with its advanced technology, ISO-certified quality standards, and commitment to fast, reliable service.

Whether you need high-precision CNC parts, custom prototypes, or injection-molded components, LS Manufacturing provides the expertise and speed to bring your ideas to life. With every project, the company proves that precision, efficiency, and innovation can go hand in hand.

Ready to Leverage These Trends for Your Business?

The future of precision manufacturing is here. Partner with LS Manufacturing to integrate cutting-edge 5-axis CNC machining, rapid prototyping, and sustainable practices into your supply chain. Get a Free, No-Obligation Quote Today and see how our precision-engineered solutions can reduce your time-to-market and costs. Visit www.lsrpf.com for an Instant Quote.