Ultrasonic hand welder is an important tool for many operators, providing the flexibility and precision needed for these delicate applications.

This article investigates how parameters like pressure, frequency, amplitude, and time affect the quality and strength of ultrasonic welds in thin materials and discusses how these parameters can be optimized for handheld ultrasonic welding.

Understanding the Handheld Ultrasonic Welding

Before exploring the optimization of specific parameters, we should first understand the fundamentals of handheld ultrasonic welding.

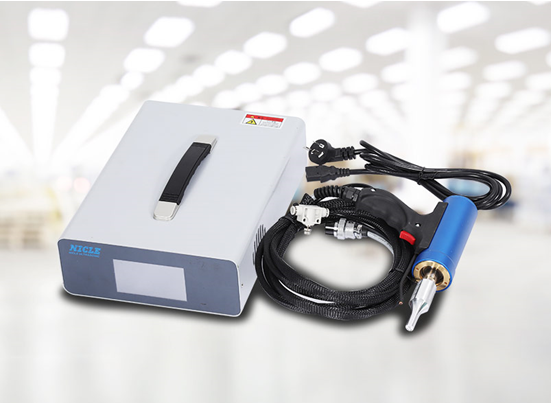

A handheld ultrasonic welder is a portable device that bonds materials using high-frequency vibrations. These vibrations create heat at the material’s contact points, fusing them together.

Among the various types of plastic welding equipment, the handheld ultrasonic welder stands out due to its ability to deliver both precision and portability. It is faster and more energy-efficient than traditional methods, making it very suitable for thin plastics, metals, and composites.

Key Parameters Affecting Handheld Ultrasonic Welding

1. Pressure

Pressure is one of the most crucial parameters when using a handheld ultrasonic welder. It refers to the force applied between the materials being welded during the ultrasonic welding process.

The right amount of pressure ensures that the materials are in direct contact, allowing the ultrasonic vibrations to create enough friction to heat the materials and bond them together.

- Insufficient Pressure: If the pressure is too low, the materials may not come into proper contact, preventing the ultrasonic energy from being effectively transferred. This leads to weak or incomplete welds.

- Excessive Pressure: Too much pressure can cause deformation or even damage to the thin materials. Over-pressurization can also wear out the ultrasonic hand welder more quickly, reducing the tool’s lifespan.

The optimal pressure setting is generally lower for thin materials to avoid deformation. For portable ultrasonic welders, this setting should be carefully adjusted to maintain effective material contact without causing damage.

2. Frequency

Frequency refers to the number of ultrasonic vibrations per second, typically measured in kilohertz (kHz). For handheld ultrasonic welders, the frequency significantly impacts the effectiveness of the process.

The correct frequency ensures that the ultrasonic waves can penetrate and generate enough heat to melt and bond the materials.

- Higher Frequencies: Frequencies in the range of 20-40 kHz are ideal for thin materials. Higher frequencies allow for more controlled energy application, which is essential for small, delicate parts. These frequencies also help minimize the risk of thermal damage to thin materials.

- Lower Frequencies: Frequencies below 20 kHz are usually used for thicker materials, but they are less effective when welding thin materials, as they generate more heat and may cause damage.

For thin materials, a portable ultrasonic welding machine with a frequency range of 30-40 kHz is often the best choice, as it provides the precision needed for delicate welding tasks.

3. Amplitude

Amplitude refers to the intensity of ultrasonic vibrations. The higher the amplitude, the more intense the energy applied, which can result in more heat and a faster welding process. However, for thin materials, it’s important to balance amplitude to avoid excessive heat generation.

- High Amplitude: A high amplitude results in greater energy transfer, leading to faster welding times. However, if the amplitude is too high for thin materials, it can cause the materials to melt too quickly, leading to deformation or even burn-through.

- Low Amplitude: Lower amplitudes reduce the energy applied and can result in weaker welds if the amplitude is too low. For thin materials, moderate amplitudes are typically ideal, as they provide sufficient energy for a strong weld without damaging the material.

The optimal amplitude for a portable ultrasonic welder when working with thin materials is typically around 60-80% of the machine’s maximum setting, which provides the right balance of energy and control.

4. Time

Welding time, or sonication time, refers to how long the ultrasonic energy is applied during the welding process. For thin materials, welding time needs to be carefully controlled to avoid overheating or damaging the parts.

- Short Welding Time: Too short a welding time may result in weak, incomplete welds, as there won’t be enough time for the material to melt and bond properly.

- Long Welding Time: On the other hand, too long a welding time can lead to overheating, material distortion, and burn-through, especially in delicate thin materials. For small parts or repairs, ultrasonic spot welders are often used for quick, localized welds.

For optimal results with portable plastic welding machines, welding times typically range from 0.5 to 2 seconds, depending on the material and the welding conditions.

Optimizing Parameters for Thin Materials

1. Pressure Settings

For ultrasonic hand welders used with thin materials, pressure settings should be moderate to avoid material distortion. Too much pressure can result in deformation, while too little pressure might not allow sufficient energy transfer.

The pressure should be adjusted depending on the material’s thickness and the specific requirements of the weld. In general, portable ultrasonic welders work best with a pressure range of 10-30% of the maximum pressure capability.

2. Frequency Selection

Higher frequencies in the range of 30-40 kHz are well-suited for thin materials. For ultrasonic spot welders used in small part assembly, these frequencies offer more precision and less heat generation, reducing the risk of damaging the thin material.

This frequency range is especially effective when welding plastics or thin metal foils, as it creates enough heat at the weld interface without causing thermal distortion.

3. Amplitude Control

The amplitude of the handheld ultrasonic welder should be moderate for thin materials, generally between 50-80% of the maximum amplitude. This ensures that enough energy is transferred to the weld interface to form a strong bond, but not so much that the material is damaged.

By carefully controlling the amplitude, operators can ensure strong, clean welds that do not compromise the integrity of the thin materials being worked on.

4. Time Optimization

For thin materials, the welding time should be as short as possible while still achieving a strong weld. For many small parts, a portable ultrasonic welding machine can create effective welds in under 1 second.

Shorter welding times reduce the risk of excessive heat buildup, which is critical for thin materials. Fine-tuning the welding time is essential, as it ensures that enough time is given for the material to melt and bond without overheating.

Benefits of Using Portable Ultrasonic Welders

The portable ultrasonic welder offers several advantages when working with thin materials. It is easy to use, highly precise, highly efficient, and especially valuable in repair and assembly tasks where small parts need to be joined quickly and securely.

The flexibility and portability of these machines allow operators to work in a wide variety of settings, from small workshops to large manufacturing lines.

The portable ultrasonic welding machine provides the benefit of being able to work on-site or in hard-to-reach areas where larger, stationary welding equipment would be impractical.

Additionally, the ultrasonic hand welder is suitable for small-scale applications where high precision is necessary. It allows for high-quality, repeatable results with minimal setup time.

Conclusion

Optimizing pressure, frequency, amplitude, and time is key to achieving reliable welds with a handheld ultrasonic welder. High frequencies (30-40 kHz), moderate pressures and amplitudes, and short welding times work best for thin materials.

As industries continue to rely on ultrasonic hand welders for efficient and precise welding, they will remain a critical tool for creating strong, durable welds in thin materials, offering a versatile and cost-effective solution for small part assembly and repair tasks.