Welcome to the fascinating world of monofilament materials, where simplicity meets innovation. These single-strand fibers have been quietly revolutionizing various industries, making them a cornerstone in both everyday applications and specialized uses. From fishing lines that withstand the toughest battles against nature to medical sutures designed for delicate procedures, monofilament materials offer unmatched versatility.

But what exactly makes these materials so remarkable? As we dive deeper into their history, advantages, and wide-ranging applications, you’ll discover why monofilaments are more than just simple threads—they’re a testament to how far material science has come. So grab your curiosity as we unravel the intricate tapestry of monofilament technology!

The History and Evolution of Monofilament Materials

The journey of monofilament materials began in the early 20th century. Initially crafted from natural fibers, these materials quickly evolved with advancements in synthetic technology.

Nylon was a groundbreaking development, introduced by DuPont in the 1930s. It marked a significant shift towards durability and flexibility. As industries sought stronger solutions, manufacturers embraced this innovation.

Throughout the decades, production techniques improved dramatically. The rise of polyester and polyethylene broadened applications significantly. These newer variants offered enhanced resistance to wear and environmental factors.

By the late 20th century, monofilament became indispensable across various sectors—fishing lines, medical sutures, and industrial uses flourished.

The evolution didn’t stop there; ongoing research has led to specialized formulations for niche applications today. Each advancement reflects an unyielding pursuit of strength combined with versatility.

Advantages of Using Monofilament Materials

Monofilament materials offer a range of distinct advantages that make them highly sought after in various applications. Their single-strand construction provides exceptional strength while maintaining lightweight characteristics.

These materials boast excellent durability, allowing them to withstand harsh environments. This resistance to wear and tear ensures longevity, reducing the need for frequent replacements.

Their smooth surface minimizes friction, making monofilaments ideal for use in situations requiring precision or minimal drag. This feature is particularly beneficial in fishing lines and medical sutures.

Monofilament’s versatility extends across industries, from textiles to aquaculture. The ability to tailor its properties—like thickness and color—enhances customization options for specific projects.

Additionally, they are often resistant to chemicals and UV light exposure, ensuring performance under varied conditions. These benefits combine seamlessly with ease of handling during manufacturing processes.

Applications of Monofilament Materials in Different Industries

Monofilament materials have carved a niche across various industries due to their versatility. In the fishing sector, monofilament lines are favored for their strength and low visibility underwater, enhancing catch rates.

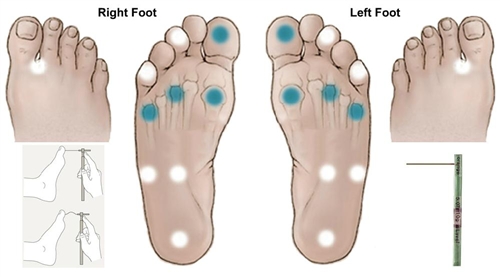

The medical field utilizes these materials in sutures and surgical meshes. Their biocompatibility ensures safety while providing durable support during healing processes.

In textiles, monofilaments contribute to innovative designs, offering unique textures in fabrics. They enable lightweight and breathable options that don’t compromise durability.

Agriculture benefits from monofilament nets for crop protection against pests or harsh weather conditions. These nets allow light penetration while keeping unwanted intruders at bay.

Even in construction, they find applications as reinforcement materials in concrete and other building components. This enhances structural integrity without adding excessive weight or bulkiness.

Their adaptability continues to open new doors across sectors seeking reliable and efficient solutions.

Types of Monofilament Material and Their Uses

Monofilament materials come in various types, each tailored for specific applications. Nylon monofilament is one of the most common. It’s known for its strength and flexibility, making it ideal for fishing lines and textiles.

Polypropylene monofilament offers excellent chemical resistance and buoyancy. This property makes it perfect for aquatic environments, such as aquaculture or water-related crafts.

For those needing durability under harsh conditions, polyester monofilament stands out. Its high UV resistance allows use in outdoor products like nets and ropes.

Polyethylene monofilament finds its niche in applications requiring low friction surfaces. It’s frequently used in conveyor belts within manufacturing sectors to enhance efficiency.

Each type of monofilament serves distinct purposes while showcasing the versatility inherent in this material class. Understanding these differences can significantly impact project outcomes across industries.

How to Choose the Right Monofilament Material for Your Project

Choosing the right monofilament material starts with understanding your project’s specific needs. Consider factors like strength, flexibility, and resistance to environmental conditions.

Next, evaluate the diameter of the monofilament. Thicker options offer greater durability but may decrease sensitivity in applications like fishing. Conversely, thinner lines can enhance performance but might sacrifice longevity.

Take into account any chemical exposure your project may encounter. Some materials resist corrosion better than others; selecting a compatible option is crucial for long-term effectiveness.

Also think about color. A visible line might be ideal for certain tasks while camouflage colors work best in other scenarios.

Don’t forget about budget constraints. Quality varies widely across brands and types, so finding a balance between cost and performance will ultimately serve your project’s success well.

Potential Challenges and Limitations of Monofilament Materials

While monofilament materials offer numerous benefits, they are not without challenges. One significant issue is their susceptibility to UV degradation. Prolonged exposure to sunlight can weaken these materials, leading to reduced performance and longevity.

Another limitation lies in flexibility. Monofilaments tend to be stiffer compared to other types of lines or threads, which may hinder applications requiring high elasticity or adaptability.

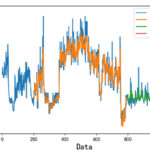

Additionally, the manufacturing process can sometimes introduce inconsistencies in quality. Variability in diameter and tensile strength could affect end-user experiences.

Cost can be a concern for some projects. High-quality monofilament options might strain budgets when large quantities are needed for specific applications. Understanding these potential downsides is crucial for making informed choices regarding material use.

Future Developments and Innovations in Monofilament Technology

The future of monofilament technology is brimming with potential. Researchers are exploring advanced polymers that enhance the strength and flexibility of these materials. This innovation could lead to lighter, more durable products.

Sustainability is also on the radar. Biodegradable monofilaments are being developed to reduce environmental impact without sacrificing performance. These eco-friendly options appeal to industries seeking greener alternatives.

Smart technology integration may be another exciting frontier. Incorporating sensors into monofilament strands could revolutionize their application in various fields, from fishing lines that detect bites to medical sutures that monitor healing.

Moreover, enhanced manufacturing techniques promise increased efficiency and reduced costs in production processes. As industries evolve, so too will the applications for monofilament materials—making them indispensable across diverse sectors like textiles and packaging.

Conclusion:

Monofilament materials have emerged as a game-changer across various industries. Their simplicity and efficiency offer remarkable benefits, making them indispensable in many applications. From fishing lines to medical sutures, their versatility knows no bounds.

Understanding the history and evolution of monofilament can provide insight into its current significance. The advantages they present are compelling—lightweight yet strong, resistant to chemicals, and customizable for specific uses.

With an array of types available, selecting the right monofilament material becomes crucial for project success. While challenges exist in terms of environmental impact or adaptability to extreme conditions, ongoing innovations promise exciting advancements on the horizon.

Embracing monofilament technology can lead to enhanced performance in your endeavors. As we look ahead, it’s clear that this simple yet effective material will continue to play a pivotal role in shaping future solutions across diverse sectors.