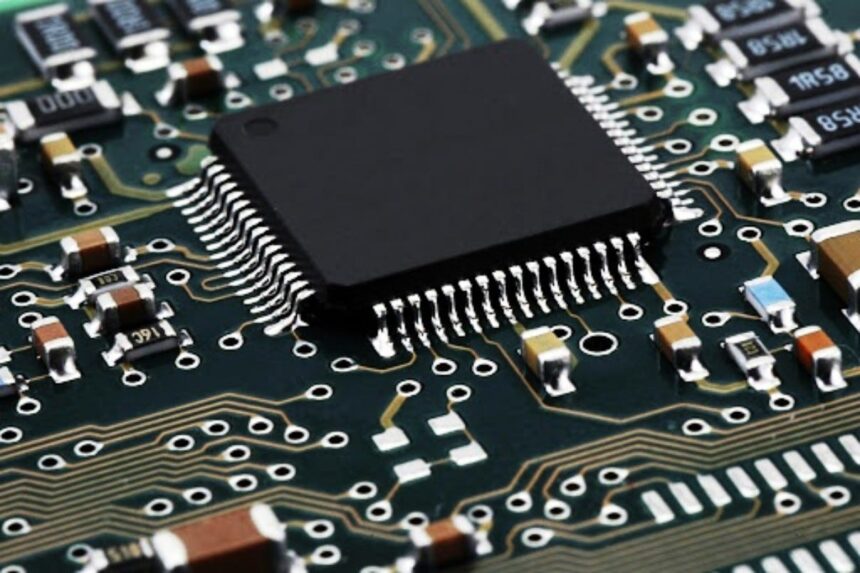

In today’s digital age, the demand for sleek and efficient electronics is growing faster than ever. Enter Surface Mount Technology (SMT), a revolutionary advancement in electronics manufacturing.

As traditional methods phase out, SMT stands as the preferred choice for high-density, compact circuit production. This shift is pivotal for designers and manufacturers striving for excellence in the tech world.

Surface Mount Technology, or SMT, is a method where electronic components are mounted directly onto printed circuit boards (PCBs). This technique contrasts with the older through-hole method that required inserting components into drilled holes.

Following this, a pick-and-place machine deftly places the components on the board. This high-tech machine quickly and accurately positions each item based on the PCB’s design.

Ultimately, rigorous testing ensures the PCB functions as intended, employing both in-circuit and functional testing methods.

Automated assembly in SMT significantly reduces human error, speeding up production and increasing reliability.

This distinction is vital for those involved in electronics production, as it clarifies the roles each term plays in the manufacturing process.

The capacity to produce reliable products at a large scale solidifies SMT as a cornerstone in electronics manufacturing.

Understanding SMT is crucial for anyone in the tech industry. Its advantages over traditional methods highlight why it’s integral to modern manufacturing.

SMT isn’t just a trend; it’s the future of electronics manufacturing. Its efficiency and dependability make it indispensable for creating the devices we use every day.

Incorporating SMT into production processes guarantees the ability to meet the increasing demand for sleek, innovative technology.