In the fast-paced world of pharmaceuticals, functionality, flexibility, and compliance are at the forefront. Capsule filling machines, which are essential for the manufacturing of capsules, have changed greatly over the years. There is an ever-growing need for high production outputs, which adds to the growing pressure for flexible equipment that is capable of meeting strict requirements.

Choosing the right pharma machine manufacturer has become extremely important for companies that are looking for optimum results in their production lines. This article analyzes the future innovations in cap filling technologies, explaining how B2B purchases need to be proactive in order to stay competitive in the global market.

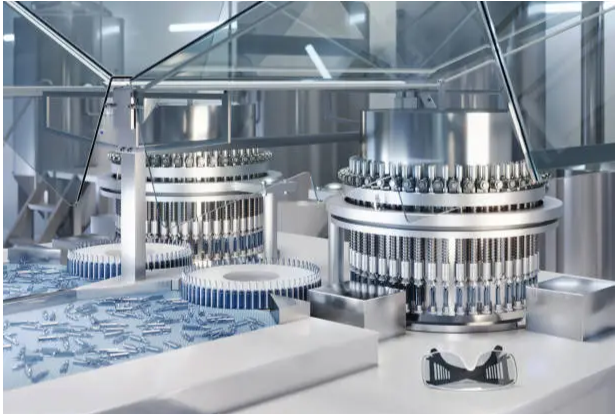

Emergence of Smart Filling Machines

The concept of Industry 4.0 has entered the world of pharmaceuticals, along with smart manufacturing cell concepts, and filling capsules is no exception. The automation, sensor, and data analytic systems that have been incorporated in capsule fillers allow manufacturers to have a real-time view of their operations.

Modern capsule filling machines now include:

- Components that predict breakdowns ahead of time.

- Adaptive intelligent dosing that self-corrects based on the flow of the material through the machine.

- Insight-driven analysis concerning yield results, OEE monitoring, and overall efficiency.

- Process integrity monitoring and deviation signaling while the capsule filler is working.

For multi-shift and multi-facility users in mid-large scale manufacturing, smart machines tackle automated control eliminating downtime while maximizing throughput. These features facilitate automated batch record production and compliance audit trails, which are critical for pharma machine manufacturers who want to future-proof their offerings.

Broader Scope of Capsule Materials and Types

The days of hard gelatin capsules being the one and only choice are long gone. We have recently seen an increase in demand brought about by health-oriented consumers and specialized drug formulations for a wider range of capsule types, including:

- Plant-derived capsules: HPMC, pullulan.

- Enteric-coated and delayed-release capsules.

- Pediatric or geriatric mini capsules.

- Micro-dose or liquid-filled capsules.

These innovative capsule filling machines are now being manufactured to accommodate such variation. Fast and flexible production without compromising accuracy is possible with tool-less changeovers, adjustable dosing stations, and servo-driven systems. Especially in contract manufacturing settings where there is a high variety of products, the ability to quickly change between different sized and different materials of capsules is a competitive advantage.

Partnering with a capsule filling machine manufacturer and pharma machine manufacturer that takes these expectations into account guarantees that your business processes remain adaptable and ready for the future.

Microdosing in the Context of High Potent Drugs Cutting Edge Technologies

The expansion of personalized medicine and the use of high-potent active pharmaceutical ingredients (HPAPIs) escalate the need for accurate microdosing. Even minute discrepancies in dosing, with respect to efficacy, could lead to significant regulatory complications.

Next-generation capsule fillers are pushing the boundaries of dosing precision with micro-tamping stations and vacuum-assisted dosing, real-time weight monitoring and feedback controls, isolated filling environments to prevent cross-contamination, specialized containment systems for operator safety.

Oncology drugs manufacturers and hormonal therapies manufacturers, along with nutraceuticals using potent ingredients, will consider these features essential. In sensitive drug applications, precision also enhances yield, reduces waste, and drives down costs.

Incorporating microdosing technology demonstrates commitment to safety and quality throughout the product lifecycle while choosing **pharma machine manufacturers ** that microdose.

Integration with Downstream and Upstream Systems

Modern capsule filling machines do not function independently. For optimal performance and effortless adherence to regulations, integration with other systems is imperative. Seamless data transfer and mechanical synchronization are possible with:

- Polishing and rejection of capsule units

- Metal detection with checkweighing

- Cartoners and packaging lines

- ERP, MES, and LIMS systems for complete traceability

These systems enable reduced manual processes, improved aids in automated decision-making across divisions, and greater real-time production control. With supply chains digitally transforming, the demand for communicative ecosystem capsule fillers will only heighten.

Pharma machine manufacturers that provide open-platform architecture alongside collaborative APIs are pioneering next-generation production facilities.

Sustainability and Energy Use

Sustainability New energy-efficient Environmentally friendly Sustainability hasn’t seamlessly integrated into everyday life. Through the eyes of regulators and general stakeholders, there is increasing focus on the environment being part of the business life. This trend creates new support from the Pharma side that results in better-designed environmentally friendly capsule filling machines.

Key features include:

- Less energy expenditure on servo motors.

- Low spoilage during product-change shutdowns or startups.

- Eco-friendly encapsulation through recyclable or compostable materials.

- Less utilization of vacuum and compressed air resources.

Sustainability strategies in conjunction with sourcing savings further enhances brand image and achieves compliance with international standards on green ethics policies for manufacturing. There is value in working with a sustainable pharma machine manufacturer beyond machinery, as it contributes in aligning with long-term ESG goals (Environmental, Social, Governance).

Predictions For The Future

In the next few years, the following capsule filling machines trends are expected to observe the most growth:

- Use of AI and machine learning for predictive performance tuning.

- Predictive monitoring and diagnostics through cloud-based solutions.

- Increase in modular designs for custom and scalable solutions.

- Single-use technology designed for targeted niches and trial clinical production.

- Advanced operator interfaces with augmented reality assisted troubleshooting.

These developments are poised to improve agility further and remove barriers for small-to-mid-sized pharmaceutical companies looking to enter the industry. In light of the increased demand for CDMOs (Contract Development and Manufacturing Organizations), versatility and compactness of capsule filling technology will be required, making it more intelligent than before.

Conclusion

An adaptive, smart, and precise future awaits capsule filling machines. B2B pharmaceutical companies need to adopt new forms of technology with emerging drug concepts and increasing regulatory scrutiny, which need flexibility and integration at a holistic level.

Investments in sustainability and phage display interactive workflows will pay dividends nurturing creativity.

Pharma machine manufacturers specializing on these technologies paired with their evolving business needs offer scaling solutions for performance upticks partnered with robust support.

Whether an enterprise or a growing contract manufacturer, productivity and competitiveness in 2025 and future years are achievable through the right capsule filling machine and pharma machine manufacturer.

Change your focus, and your capsule production line will outshine the competition instead of merely matching their speed.