In modern industrial automation, the MVI69L-MBTCP module serves as a critical bridge between Modbus TCP networks and legacy control systems, making its availability essential for maintaining production uptime. When these components fail, manufacturers face immediate pressure to source replacements quickly while managing tight budgets and avoiding costly downtime. The challenge intensifies when dealing with surplus control system parts, where availability fluctuates and lead times can stretch from days to months depending on the supplier. Many facilities struggle to balance the urgency of repairs against the need for verified, compatible components that won’t compromise system integrity. Finding reliable OEM automation spare parts requires navigating a complex landscape of authorized distributors, surplus suppliers, and secondary markets. This article explores proven strategies for rapidly sourcing MVI69L-MBTCP control system parts, from identifying trustworthy suppliers to verifying component quality. Whether you’re managing emergency replacements or building strategic inventory, understanding these sourcing methods will help you minimize downtime and control costs effectively.

Understanding MVI69L-MBTCP Control System Components

The MVI69L-MBTCP module functions as a communication gateway that enables Allen-Bradley CompactLogix and MicroLogix controllers to exchange data with Modbus TCP/IP devices across Ethernet networks. This interface card translates protocols in real-time, allowing older Modbus equipment to integrate seamlessly with modern Rockwell Automation platforms without requiring complete system overhauls. Manufacturing facilities commonly deploy these modules in applications ranging from SCADA systems monitoring remote sensors to production lines coordinating packaging equipment with central control systems. The module supports up to 32 simultaneous Modbus TCP client connections and can handle both discrete and analog data types, making it versatile across diverse industrial environments.

These components typically integrate into systems managing water treatment facilities, food processing operations, material handling conveyors, and energy distribution networks where legacy Modbus devices remain operational alongside newer programmable logic controllers. The most frequent failure points include corrupted firmware from power surges, physical damage to Ethernet ports from improper cable handling, and communication errors caused by network configuration conflicts. Memory chip degradation after years of continuous operation can also trigger intermittent connectivity issues. Understanding these failure patterns helps maintenance teams diagnose problems quickly and identify whether they need complete module replacement or can resolve issues through firmware updates. The module’s position as a single point of failure in many communication architectures makes maintaining spare inventory or knowing rapid sourcing channels essential for preventing extended production stoppages.

Top Challenges in Sourcing Automation Spare Parts

Global supply chain disruptions have significantly impacted the availability of surplus control system parts, with semiconductor shortages and manufacturing delays creating unpredictable inventory levels across the automation industry. Many facilities discover that modules listed as “in stock” by distributors actually require 8-12 week lead times due to backorders at manufacturing plants. This uncertainty forces maintenance teams to expand their supplier networks beyond traditional channels, often contacting multiple vendors simultaneously to locate available inventory. Geopolitical factors and shipping container shortages further complicate international sourcing, particularly when components originate from specific manufacturing regions.

Cost considerations present another significant obstacle when sourcing OEM automation spare parts. New MVI69L-MBTCP modules from authorized distributors command premium pricing that strains maintenance budgets, especially for facilities requiring multiple units or building backup inventory. The price gap between new OEM parts and refurbished surplus components can reach 40-60%, creating pressure to consider secondary market options despite potential quality concerns. Emergency procurement situations eliminate negotiating leverage, forcing buyers to accept expedited shipping fees and inflated pricing. Lead time pressures compound these financial challenges when production downtime costs exceed part prices by orders of magnitude. Facilities must often choose between paying premium rates for immediate availability or risking extended downtime while waiting for lower-cost alternatives to arrive, with each hour of stopped production potentially costing thousands in lost revenue and contractual penalties.

5 Reliable Methods to Source MVI69L-MBTCP Parts Quickly

Method 1: Authorized OEM Distributors

Start by contacting Rockwell Automation’s official distributor network, which you can locate through their website’s “Where to Buy” tool by entering your location and specific part number. Authorized distributors like Kendall Electric, Rexel, and CED provide guaranteed authentic components with full manufacturer warranties, eliminating risks associated with counterfeit parts. Request stock checks across multiple regional warehouses simultaneously, as inventory often varies between distribution centers even within the same company. While OEM channels typically carry higher price points, they offer immediate technical support for installation issues and can expedite cross-shipments from other locations when local stock depletes. Many distributors maintain emergency hotlines for critical downtime situations, providing after-hours access to inventory specialists who can arrange same-day courier delivery or will-call pickup for urgent needs.

Method 2: Specialized Surplus Parts Suppliers

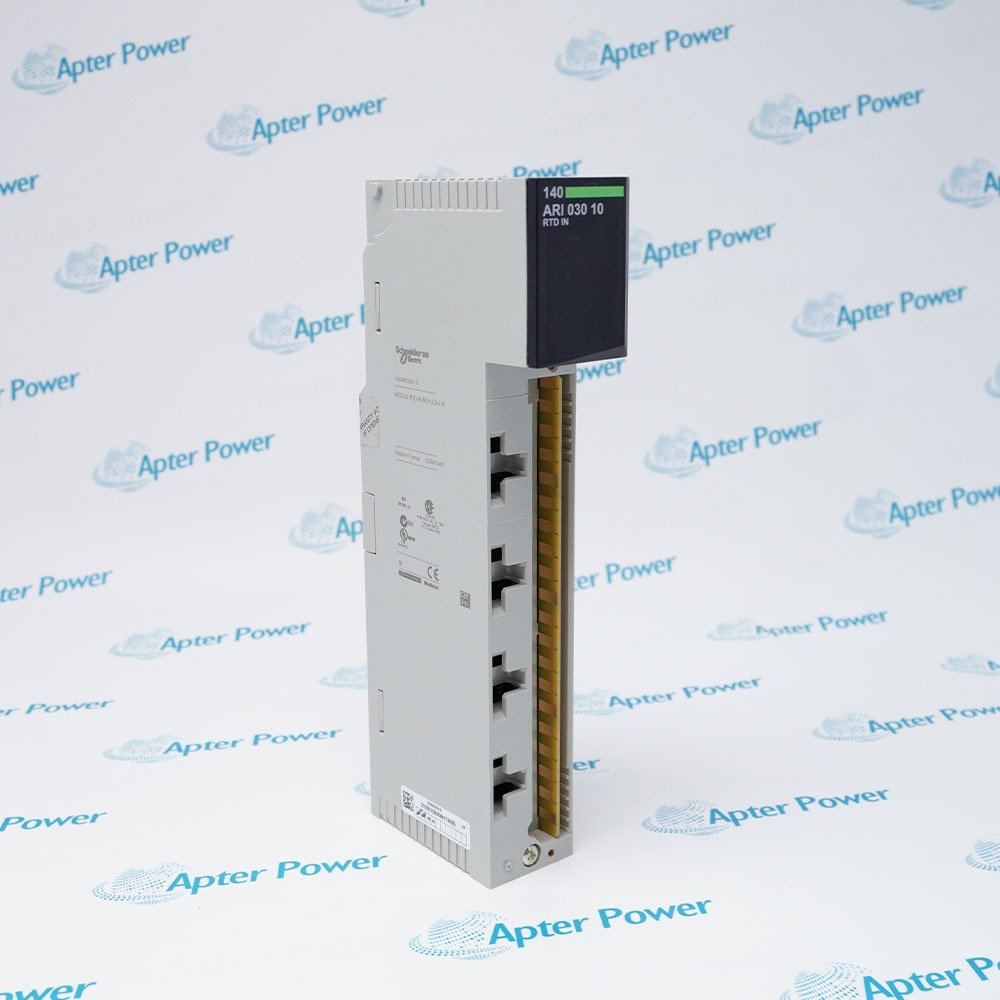

Surplus automation suppliers acquire excess inventory from plant closures, system upgrades, and distributor overstock, offering functional components at substantially reduced costs compared to new OEM parts. Reputable surplus vendors like Apter Power and regional industrial liquidators test components before listing them for sale, often providing limited warranties ranging from 30 days to one year. Before purchasing, request detailed documentation including the part’s service history, storage conditions, and any refurbishment performed. Examine high-resolution photos of the actual unit rather than stock images, checking for corrosion on circuit boards, damaged connectors, or missing mounting hardware. Ask suppliers about their return policies and whether they offer advance replacement options if the component fails functionality testing in your system. Established surplus dealers typically maintain relationships with testing facilities that can verify communication protocols and firmware versions match your system requirements.

Method 3: Online Industrial Marketplaces

Platforms like eBay Industrial, Automation24, and specialized sites such as PLCCenter aggregate listings from multiple sellers worldwide, expanding your sourcing options beyond local suppliers. Use advanced search filters to sort results by seller ratings, return policies, and shipping locations to identify trustworthy vendors with proven track records. Verify seller credentials by checking their feedback history specifically for automation components, looking for comments about accurate part descriptions and proper packaging methods. Contact sellers directly before purchasing to confirm the part number matches exactly, request additional photos of serial number plates, and inquire about testing procedures they’ve performed. Enable price tracking alerts on these platforms to monitor availability fluctuations and receive notifications when new listings appear below your target price point. Always use payment methods offering buyer protection, and document all communications with sellers to support potential dispute resolutions if components arrive damaged or incompatible.

Method 4: Local Industrial Equipment Auctions

Industrial liquidation auctions occur regularly when manufacturing facilities close, relocate, or upgrade control systems, offering opportunities to acquire MVI69L-MBTCP modules at fraction-of-retail pricing. Monitor auction houses like Machinery Auctioneers and Bid on Equipment for upcoming sales in your region, reviewing online catalogs that typically post 1-2 weeks before auction dates. Attend preview days when available to physically inspect components, bringing a laptop to check serial numbers against Rockwell’s product verification databases. Establish maximum bid limits before auctions begin to avoid emotional overspending during competitive bidding situations, factoring in buyer’s premiums typically ranging 10-18% above hammer prices. Consider partnering with other facilities to purchase lot quantities containing multiple modules, then dividing components and costs proportionally. Build relationships with auction house staff who can notify you when control system equipment enters their inventory before public listings appear.

Method 5: Networking with Other Manufacturers

Join industry-specific forums like PLCS.net and LinkedIn groups focused on Rockwell Automation users, where maintenance professionals frequently post surplus inventory available for direct sale or trade. Attend regional automation user group meetings and trade association events where informal parts exchanges occur between facilities using similar equipment platforms. Create a standardized parts-wanted list with specific part numbers and acceptable condition grades, distributing it through your professional network and industry contacts quarterly. Establish reciprocal arrangements with non-competing manufacturers in your area, agreeing to share emergency spare inventory during critical downtime situations with predetermined borrowing terms. Many facilities maintain excess stock from bulk purchases or obsolete system upgrades, making them willing to sell components at cost rather than letting inventory sit unused. Document these informal supplier relationships in your maintenance management system so multiple team members can access contacts during emergency situations when primary procurement staff aren’t available.

Evaluating Quality and Compatibility of Control System Parts

Begin quality verification by confirming the exact part number matches your system requirements, checking that the MVI69L-MBTCP designation includes the correct suffix letters indicating firmware revision and communication protocols. Compare the module’s catalog number against Rockwell Automation’s product compatibility matrix to ensure it supports your controller series and firmware version. Request the module’s serial number and manufacturing date code, then cross-reference these against known product revisions to identify any obsolete versions with documented communication bugs or security vulnerabilities. Examine the physical condition carefully, looking for discoloration on circuit boards that indicates overheating, checking connector pins for bent contacts or corrosion, and inspecting the housing for cracks that might compromise electromagnetic shielding.

Implement functional testing before installation by connecting the module to a bench-test setup that simulates your network environment, verifying it establishes Modbus TCP connections and exchanges data packets without errors. Use Rockwell’s RSLinx software to detect the module on the network and confirm its configuration parameters load correctly. Test all Ethernet ports under load conditions, monitoring for packet loss or latency issues that could indicate degraded network interface components. Run diagnostic commands to check internal memory integrity and verify the firmware version matches your system documentation. For surplus parts, request documentation of any refurbishment work performed, including component replacements and calibration certificates. Compare the module’s MAC address against Rockwell’s registered ranges to confirm authenticity, as counterfeit components often use improperly formatted addresses. Document all test results and retain them with the component’s maintenance records for future troubleshooting reference.

Cost-Saving Strategies for Automation Spare Parts

Implementing bulk purchasing agreements with authorized distributors can reduce per-unit costs by 15-30% when committing to annual volume targets for commonly replaced components like MVI69L-MBTCP modules. Negotiate blanket purchase orders that lock in pricing for 12-month periods while allowing flexible delivery schedules aligned with your actual consumption patterns. Pool purchasing power with other facilities in your corporate network or through industry consortiums to reach volume discount thresholds that individual sites cannot achieve alone. Many distributors offer additional price reductions when combining orders for multiple part numbers in single shipments, reducing freight costs while simplifying receiving processes.

When OEM parts become unavailable or prohibitively expensive, explore functionally equivalent alternatives from the same manufacturer’s product line that offer identical communication capabilities with different form factors or connector types. Some facilities successfully deploy newer module revisions like the MVI69L-MBTCP2 with adapter brackets, gaining improved performance while accessing better inventory availability. Consider refurbished units from certified repair centers that replace worn components and update firmware, typically offering warranties comparable to surplus parts at 25-40% below new OEM pricing. Extend component lifespan through preventive maintenance practices including quarterly firmware backups, annual connector cleaning with approved contact solutions, and environmental monitoring to prevent exposure to temperature extremes or humidity levels exceeding manufacturer specifications. Install surge protection devices on network connections and implement redundant power supplies to minimize electrical stress that accelerates component degradation. Maintain detailed failure analysis records to identify patterns suggesting systemic issues rather than random component failures, allowing you to address root causes instead of repeatedly replacing parts. Establish minimum-maximum inventory levels based on historical failure rates and lead times, automating reorder triggers through your maintenance management system to prevent emergency purchases at premium pricing.

Strategic Sourcing for Minimized Downtime

Sourcing MVI69L-MBTCP control system parts quickly requires a multi-channel approach that combines authorized OEM distributors for guaranteed authenticity with specialized surplus suppliers offering cost-effective alternatives. The five methods outlined—from leveraging online industrial marketplaces to building manufacturer networks—provide complementary strategies that address different urgency levels and budget constraints. Success depends on verifying component compatibility through rigorous testing procedures and maintaining detailed documentation of serial numbers, firmware versions, and physical condition assessments. Facilities that implement proactive spare parts management, including strategic inventory levels based on historical failure data and established relationships with multiple supplier types, significantly reduce downtime risks during critical component failures. The balance between cost savings and reliability ultimately comes down to thorough quality evaluation processes and understanding when premium OEM pricing justifies the investment versus when tested surplus components meet operational requirements. By diversifying sourcing channels and maintaining current knowledge of market conditions, maintenance teams can secure necessary automation components rapidly while controlling procurement costs. Investing time in building these supplier relationships and verification protocols before emergencies occur transforms reactive crisis management into strategic asset protection that keeps production systems running efficiently.