In this industry, packaging serves as a consumer’s first touchpoint with the product, underscoring its decisive role in purchase decisions. For B2B companies in the fragrance industry, choosing the right fragrances bottle manufacturer can greatly increase marketability, improve brand perception, and provide reliable quality control throughout large runs. Strangely, a number of specialized areas that cover fragrances also apply to the work of glass jar manufacturers with regard to precision, customization, and production efficiency.

I aim to highlight the value of skilled manufacturers and its impact on product appeal and business growth which in turn, helps to thrive in the competitive market.

Tasking a Fragrances Bottle Manufacturer in Market Positioning

A fragrances bottle manufacturer operates as a brand image marketer aside from being a mere supplier to the business. With multiple fragrance products from different companies in the market, packaging is essential in standing out with the visual identity of a brand.

A manufacturing partner enables businesses to:

- **Communicate the brand’s vision and narratives in bottle shapes, textures, and finishes.”

- Achieve product uniqueness with distinctive fragrances and decorative features.

- Ensure reliability in operation using controlled quality components like sprayers, caps, and seals.

- Maintain visual coherence over several product ranges and across different countries.

Brand fragrances can be differentiated in the market by closely collaborating with a manufacturer to integrate packaging with market dynamics, aligning customer satisfaction, and strategic objectives.

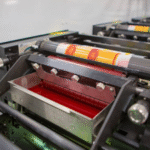

How Industrial Know-How Improves the Attractiveness of Products

Technically skilled glass jar manufacturers and perfume bottle experts know the intersection of craftsmanship and accuracy. The appearance, texture, and durability of the product undergoes changes qualitatively and quantitatively with each process from the raw materials to the final decorative coating.

These are essential ways in which manufacturing know-how enhance a product’s attractiveness and increase its marketability:

- Material Quality – The high purity of the glass guarantees crystal clarity, correct color, and freedom from staining or chemical reactions with the fragrance formulation.

- Design Innovation – Creativity and brand image are taken care of with advanced mold-making technologies which enable distinctive shape design.

- Surface Decoration – Depth and sophistication can be added through frosted finish, metallization, or color gradients.

- Structural Integrity – Robust design for the bottle allows for surviving transit and storage, maintaining design aesthetics.

Rest assured for B2B buyers, these features do not just appeal visually. The look and these attributes shape the perception of the quality and value of the product.

Customization: The Key To Differentiating Your Brand

In the fragrance niche, the option for Customization greatly enhances how a product can be marketed. Whether it be a luxury fragrance or a mass marketed perfume, custom design always aids the product in connecting with prospective customers.

A professionally qualified hyped fragrance bottle manufacturer can offer:

- Bespoke Shapes and Sizes – Including and balancing the packaging’s shape and size with the branding and the product’s intended usage.

- Special Color Treatments – Packaging can be Splashy or Low Key in Color. It can be Transparent or Brightly Colored, Startlingly Bright, Deep, and Bold Shades.

- Special Textures – Embossing, engraving textures for the product.

- Cap and Closure Variety – Including and balancing the packaging’s shape and size with the branding and the product’s intended usage, custom covers can include decorative collars, magnetic caps, or integrated spray systems.

- Branding Integration – Labeling and printing which directly incorporates logos and design motifs of the brand.

The described custom features improve the aesthetic of the product and improve brand recall, building brand loyalty in highly competitive industries.

The Importance of Scalability and Lead Time Management

For B2B fragrance companies, seasonal campaigns, trade shows, or promotional windows tend to create a structured timeline that product launches must fit. In these scenarios, timelines set by glass jar manufacturers and perfume bottle producers become the most crucial factors.

When looking for a manufacturing partner, it is crucial to assess the following:

- Production Capacity – Is the factory capable of maintaining quality during peak orders?

- Lead Time Reliability – Is the factory consistent in meeting delivery deadlines?

- Mold Development Speed – What is the time frame for a new design’s execution from its concept stage?

- Inventory Management – Does the manufacturer provide warehousing services to streamline the supply chain?

Manufacturers equipped with sophisticated production plants, automated inspection systems, and experienced logistics teams are better positioned to meet both standing and emergent demand shocks without delays.

Quality Assurance and Global Compliance

A beautifully crafted perfume bottle is essentially worthless without clear quality and safety limits. Thus, B2B fragrance companies need to make sure that their fragrance bottle manufacturer enforces strict quality management and international compliance during production.

Quality and compliance encompasses the following:

- ISO-Certified Production – Proof of consistent manufacturing quality.

- Third-Party Testing – Glass composition, coating safety, and packaging scrutiny.

- Automated Inspection Systems – Identifying and eliminating factory defects.

- Regulatory Compliance – Meeting safety standards for the designated markets: EU, North America, and Asia.

Through compliance, businesses are able to protect their brand’s reputation, avoid expensive recalls, and simplify access to multiple international markets.

Cooperation for Sustained Marketplace Success

Ideally, the bond between a fragrance company and its production partner should be cooperative and hinged on trust, collective collaboration, and communication towards similar goals. B2B companies using their glass jar manufacturers or perfume bottle suppliers as strategic partners tend to be more creative and more profitable.

Through cooperation, businesses in B2B cooperate with their suppliers in the following manners

- Regular Progress Updates – enabling the addition of last minute design changes and production quality control.

- Post Launch Support – Continuously or periodically providing components that are designed, marketed, and photographed.

- Prototyping and Testing – testing market and design reception before large scale production

- Detailed Project Briefs – Every one of the participants in the design, budget, and market goals should be on the same page

Long standing relationships with manufacturers or suppliers lead to easily applying innovative methods over a period of time as the partner accumulates knowledge of the brand’s preferences, processes, and positioning in the market.

Conclusion

In the fragrance industry, packaging serves a dual purpose: it protects the product and serves a critical role in marketing that shapes the buyer’s perception and influences them to purchase the product. The right fragrances bottle manufacturer can integrate a brand’s market presence by strategic creative personalization, scalable production, and meticulous quality assurance.

With experienced glass jar manufacturers, B2B companies can gain a broader scope of faster time-to-market and enhanced designs that integrate beauty with functional reliability. In an industry where first impressions matter, the right manufacturing partnership becomes a key aspect in attaining and sustaining market success.