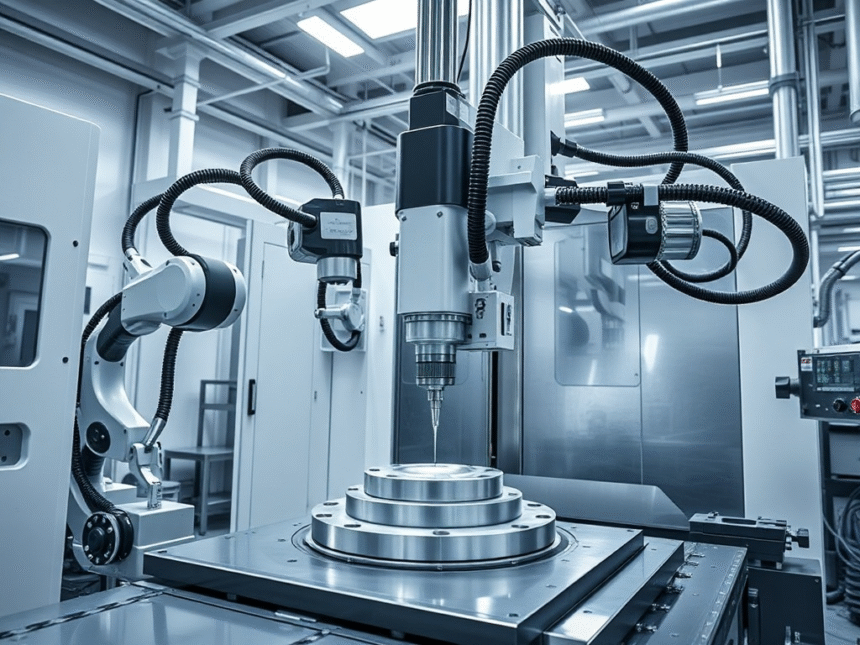

Speed and precision are critical in modern fabrication. Businesses must be able to move from design to delivery quickly, without sacrificing quality. A well-integrated CNC machining centre provides the technology to achieve this, offering automated control over cutting, drilling, milling, and shaping tasks. These systems allow manufacturers to handle both small-scale prototyping and high-volume production with efficiency and confidence.

By removing many of the variables associated with manual processes, CNC systems ensure that each part produced aligns with exact specifications. This reliability not only reduces waste but also shortens project timelines, helping companies meet tight deadlines in competitive markets.

Accelerating the Prototyping Phase

In the past, developing prototypes often involved long lead times and multiple iterations, particularly when complex designs were involved. CNC machining has changed this, enabling engineers to move directly from CAD models to physical components with minimal delay. This reduces the time spent between design, testing, and refinement, allowing products to reach the market faster.

Because prototypes can be produced with the same precision as production parts, testing becomes more reliable. Manufacturers can identify flaws early and make design adjustments before committing to full-scale production, saving both time and resources.

Supporting High-Volume Consistency

When moving from prototypes to production runs, consistency becomes the key challenge. Each component must be identical, meeting the same dimensional tolerances and surface finishes. CNC machining centres excel here, using computer control to eliminate human error and ensure repeatability across thousands of units.

This level of accuracy helps streamline downstream processes. Parts produced with consistent dimensions are easier to assemble, require less rework, and help maintain the integrity of the finished product. For industries such as aerospace, automotive, and construction, this predictability is vital.

Flexibility for Complex Projects

Modern designs often call for intricate shapes, tight angles, and multi-axis machining. Traditional methods can struggle with this complexity, but CNC systems are capable of executing advanced geometries without sacrificing precision. Multi-tool setups allow different operations to be performed in one cycle, reducing handling and further speeding up production.

This flexibility supports innovation. Designers can push creative boundaries, confident that their concepts can be manufactured efficiently. As customer demand shifts towards bespoke or high-performance solutions, this adaptability becomes a competitive advantage.

Efficiency and Cost Management

Automated machining also improves cost control. By optimising cutting paths and reducing material waste, CNC centres make better use of raw materials. At the same time, fewer errors and faster cycles reduce labour costs and downtime.

When combined with energy-efficient technologies, these systems contribute to more sustainable operations. Manufacturers can lower costs while also meeting environmental goals, aligning production efficiency with long-term business strategy.