In the complex world of industrial pipeline management, maintaining operational continuity while performing essential modifications and repairs represents one of the industry’s most significant challenges. Hot tapping, also known as pressure tapping or under pressure drilling, has emerged as a crucial technique that allows engineers to connect to existing pipelines without interrupting flow or requiring system shutdown.

Understanding Hot Tapping: A Critical Industry Solution

Hot tapping refers to the specialized process of making a connection to an existing, pressurized pipeline without interrupting the system’s operation. This technique has revolutionized how the energy, water, gas, and industrial sectors approach infrastructure modifications and expansions.

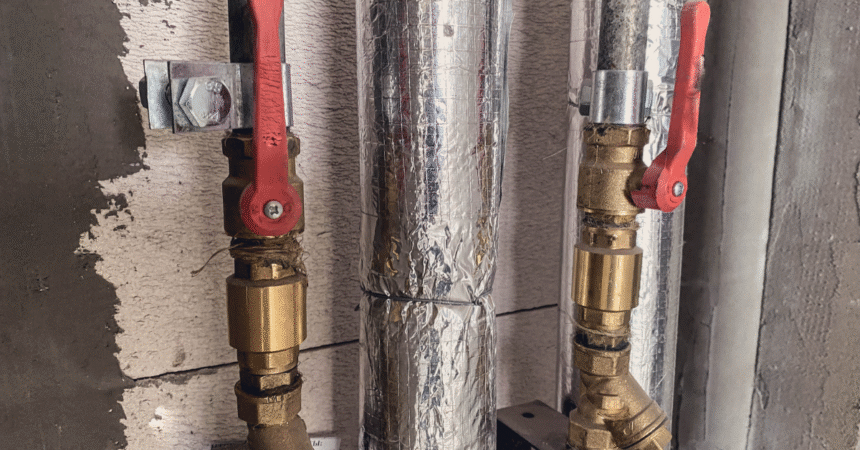

At its core, hot tapping involves attaching a fitting (either welded or mechanical) to the existing pipe, installing a valve, connecting a specialized tapping machine, and drilling through the pipeline wall while maintaining system pressure and product flow. The result is a new branch connection that’s been created without any service interruption or product loss—a remarkable engineering achievement with significant economic and safety benefits.

The Evolving Role of Hot Tapping in UK Infrastructure

The United Kingdom’s extensive network of pipelines transporting everything from natural gas and oil to water and industrial chemicals represents critical national infrastructure. As these systems age and as demands change, the ability to modify, repair, and expand them without disruptive shutdowns has become increasingly valuable.

Hot tapping has found particularly important applications in several key sectors across the UK:

Energy Sector Applications

The UK’s energy infrastructure relies heavily on pipeline networks for transferring oil, gas, and other resources. Hot tapping enables these critical systems to be modified or expanded while remaining operational, preventing costly shutdowns and potential energy supply disruptions. For power generation facilities, hot tapping allows for essential maintenance without compromising the continuity of electricity production.

Industrial Manufacturing

In manufacturing plants where process pipelines are essential to operations, shutdowns can cost thousands of pounds per hour. Hot tapping provides a means for installing new equipment, creating bypass systems, or performing necessary modifications without halting production. This capability directly translates to significant cost savings and improved operational efficiency.

Municipal Services

Water supply networks throughout the UK benefit substantially from hot tapping techniques. Urban expansion and infrastructure upgrades often require connections to existing water mains—hot tapping ensures these modifications can be made without interrupting water service to residents and businesses, a critical consideration for public health and convenience.

Technical Considerations and Safety Standards

While hot tapping offers remarkable benefits, it requires specialized expertise, proper risk assessment, and adherence to rigorous safety standards. Not all pipelines are suitable candidates for hot tapping—factors including pipe material, wall thickness, contents under pressure, temperature, and flow rates must all be carefully evaluated before proceeding.

Industry professionals follow comprehensive standards for hot tapping operations, including:

- Detailed pre-job risk assessments

- Thorough inspection of pipe conditions

- Pressure and temperature verification

- Selection of appropriate equipment rated for specific applications

- Implementation of proper isolation procedures when necessary

- Engineering calculations to ensure structural integrity

- Comprehensive documentation and quality control measures

RDS Pipeline: Setting the Industry Standard in the UK

With over two decades of specialized experience in pipeline isolation solutions, RDS Pipeline has established itself as an industry leader in hot tapping services across the United Kingdom. Our approach combines technical excellence with a commitment to safety and customer satisfaction.

What sets RDS Pipeline apart in the competitive hot tapping landscape:

Technical Expertise and Specialized Equipment

Our engineers possess extensive experience working with diverse pipeline materials including stainless steel, carbon steel, ductile iron, cast iron, asbestos cement, and various plastic and composite materials. This versatility allows us to tackle projects across multiple industries with confidence and precision.

RDS Pipeline maintains a comprehensive range of specialized hot tapping equipment capable of handling pipes from 1/2″ up to 48″ in diameter, with temperature ranges from below freezing to over 200°C, and pressures up to 40 bar. This technical capability enables us to address virtually any hot tapping challenge encountered in industrial settings.

Commitment to Safety and Standards

Every hot tapping operation conducted by RDS Pipeline adheres to rigorous safety protocols and industry best practices. Our technicians receive continuous training on the latest techniques and equipment, ensuring that each project is completed with maximum attention to safety and quality.

We implement comprehensive risk assessment procedures before any hot tapping operation, identifying potential hazards and establishing clear mitigation strategies. This proactive approach to safety has earned us a reputation for reliability and professionalism among our diverse client base.

Client-Focused Service Philosophy

At RDS Pipeline, we recognize that effective communication is as important as technical expertise. Our team provides transparent project planning, regular updates, and clear documentation throughout the hot tapping process. We understand that each client’s pipeline system is unique, and we tailor our approach to address specific requirements and concerns.

This client-focused philosophy extends to providing expert guidance on when hot tapping is appropriate and when alternative methods might be more suitable. Our commitment to honest professional advice has built lasting relationships with clients across various sectors including hospitals, civil engineering firms, facility management companies, energy providers, and commercial entities throughout the UK.

Case Study: Innovative Solutions in Action

A recent project exemplifies RDS Pipeline’s problem-solving approach: When a major UK industrial facility needed to add multiple branch connections to their high-pressure process pipeline system without disrupting production, they faced significant technical challenges due to space constraints and variable operating pressures.

The RDS Pipeline team conducted a comprehensive site survey and developed a customized hot tapping solution utilizing specialized equipment adapted for the limited workspace. By implementing a carefully sequenced operation plan and deploying our most experienced technicians, we successfully completed all branch connections while the system remained fully operational—saving the client an estimated £180,000 in avoided shutdown costs.

The Future of Hot Tapping Technology

As infrastructure needs evolve and new materials and systems emerge, hot tapping techniques continue to advance. RDS Pipeline remains at the forefront of these developments, investing in next-generation equipment and training programs to maintain our position as industry leaders.

Emerging trends in the hot tapping field include:

- Advanced non-destructive testing methods for pre-tap pipeline assessment

- Improved mechanical fitting designs for enhanced reliability

- Development of specialized tools for composite and high-tech pipeline materials

- Integration of digital monitoring systems for precision control during tapping operations

- Enhanced safety systems for high-risk applications

Choosing the Right Hot Tapping Partner

For organizations considering hot tapping services, selecting the right contractor is critical. Key factors to evaluate include:

- Verifiable experience with similar applications and materials

- Comprehensive safety record and clearly defined safety protocols

- Quality and condition of specialized equipment

- Proper certifications and adherence to industry standards

- Ability to provide detailed method statements and risk assessments

- References from previous clients with similar requirements

Conclusion: The Value of Expertise in Critical Infrastructure

As the UK continues to invest in maintaining and upgrading its essential pipeline infrastructure, the importance of specialized services like hot tapping will only increase. The ability to modify, repair, and expand these critical systems without disruption represents not just an engineering achievement but a significant economic advantage.

RDS Pipeline remains committed to providing the highest quality hot tapping services across the United Kingdom, combining technical excellence with a customer-focused approach that prioritizes safety, efficiency, and clear communication. Our two decades of specialized experience have established us as trusted partners for the most demanding pipeline projects across multiple industries.

For organizations facing pipeline modification challenges, engaging with experienced specialists like RDS Pipeline early in the planning process can identify opportunities to implement hot tapping solutions that minimize disruption while maintaining system integrity and operational continuity.