Appliance production today moves at a pace that leaves little room for inefficiency. Manufacturers face pressure to deliver higher volumes, control costs, and maintain consistent quality across every product line. Meeting these demands requires more than just skilled labor and reliable machinery. It calls for systems that keep materials, components, and finished goods moving smoothly.

This is where conveyor systems quietly take center stage. Far from being a background utility, they drive efficiency, improve workplace safety, and give businesses the flexibility to adapt to changing production needs. In this post, we’ll explore how conveyors support scaling efficiency in appliance manufacturing, the benefits they bring to modern plants, and why SanHok, the leading appliances Assembly Line & Conveyor Manufacturer, has become a trusted name for companies looking to build reliable, future-ready systems.

From Simple Belts to Smart Systems: How Conveyors Have Changed

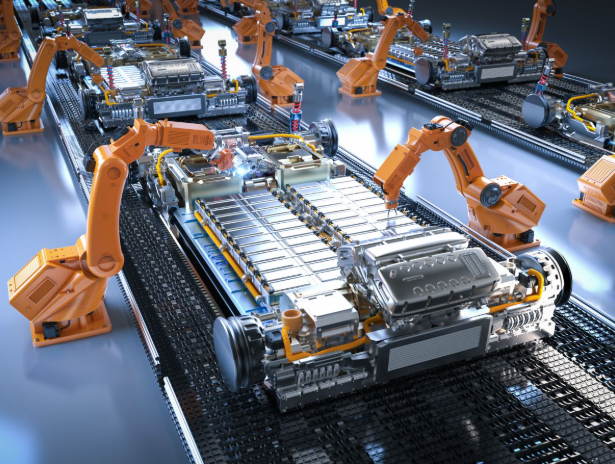

Early assembly lines introduced conveyors as simple belt systems designed to move parts from one station to the next. They transformed mass production but offered little flexibility or precision. Over time, as appliance manufacturing advanced, the demands on conveyor systems changed.

Modern conveyors are smarter, safer, and adaptable to the evolving needs of manufacturers. Integrated sensors, automated controls, and modular designs allow businesses to adjust production lines quickly and with minimal downtime. For appliance makers, this evolution is not just technological progress. It is a competitive necessity, where speed, quality, and efficiency directly influence long-term success.

Boosting Output Without Adding More Hands

In modern factories, speed and consistency define success. Conveyor systems make it possible to move more products through the line without increasing labor requirements. By cutting down on manual handling, they reduce the time workers spend lifting, carrying, and transferring parts between stations. This shortens cycle times and prevents bottlenecks that slow output.

Consider an assembly line where components such as motors, wiring, and casings are delivered automatically to the right workstation at the right moment. Finished appliances then flow directly into packaging or shipping, keeping production steady and predictable. The result is a continuous process with fewer interruptions and faster turnaround times.

The business impact is clear: higher throughput without inflating payroll costs. Manufacturers can meet rising demand with the same workforce while improving accuracy and consistency. Industry leaders like SanHok design conveyor solutions with this goal in mind, giving companies the tools to scale production efficiently in competitive markets.

Safer Workplaces, Happier Teams

Behind every appliance produced is a workforce that deserves a safe and supportive environment. Conveyor systems reduce physical strain from lifting, bending, and repetitive tasks. By taking over the heavy work, they lower the risk of injuries that can disrupt both employee health and production schedules.

Safety is more than compliance; it directly affects morale. Workers who feel supported are more engaged and consistent in their performance. Fewer injuries also mean fewer disruptions, which keeps production timelines intact and avoids costly downtime.

Forward-thinking partners such as SanHok design conveyor solutions with ergonomics in mind. Their systems help businesses protect employees while maintaining smooth, reliable operations.

Flexibility That Keeps You Competitive

Appliance manufacturing is constantly changing. New models, updated features, and shifts in consumer demand require production lines that can adapt quickly. Modular conveyor systems provide this flexibility by allowing sections to be added, removed, or reconfigured without halting operations.

For example, when a new appliance model is introduced, conveyors can be adjusted to accommodate different dimensions or assembly requirements. The ability to make quick changes keeps production running smoothly and reduces downtime.

In today’s competitive environment, agility is as important as output. Companies that adapt quickly to market shifts are the ones that thrive. By working with experts like SanHok, manufacturers gain conveyor solutions that support rapid adjustments and keep them ahead of changing industry demands.

Automation in Action: Smarter Conveyors for Smarter Plants

Automation has transformed conveyors into smart systems that improve precision and consistency. With sensors and automated controls, conveyors can regulate speed, detect jams, and redirect products without manual intervention. This reduces human error and ensures steady, predictable output.

Real-time tracking adds further value. Conveyors equipped with sensors provide data for quality control, identifying problems before they spread through the line. Manufacturers can respond faster, reduce rework, and keep defective products out of circulation.

From a business perspective, automation delivers measurable benefits: less waste, lower costs, and dependable throughput that meets customer expectations. SanHok leads in developing conveyor solutions that combine automation with durability, giving appliance manufacturers reliable tools to operate smarter and scale production with confidence.

Lean Manufacturing’s Best Friend

Lean manufacturing depends on materials moving at the right pace without delays or excess. Conveyor systems naturally support this by aligning with “just-in-time” production methods. Instead of building up inventory between stations, they deliver components exactly when needed.

This flow reduces clutter, minimizes downtime, and keeps workers focused on value-adding tasks rather than material handling. Managers gain assurance that schedules remain consistent and resources are used efficiently.

For appliance manufacturers, conveyors are more than a convenience. They are practical tools for applying lean principles. With efficiency-focused designs from leaders like SanHok, businesses can streamline operations while supporting continuous improvement goals.

What’s Next: Smarter, Greener Conveyor Technology

The future of conveyors lies in systems that combine efficiency with sustainability. Energy-efficient motors and lightweight materials are helping manufacturers cut power consumption. IoT integration allows conveyors to connect with other equipment, providing predictive maintenance alerts that prevent breakdowns before they occur.

For appliance producers, these advances matter. Smarter systems reduce downtime, lower operating costs, and support sustainability initiatives that customers increasingly value. Forward-looking investments in greener conveyor technology also build long-term competitiveness by delivering efficiency gains year after year.

With forward-thinking partners like SanHok, manufacturers can adopt conveyor solutions that deliver both immediate performance benefits and lasting value, keeping production lines ready for growth and aligned with sustainability standards.

Conclusion: Building Efficiency That Lasts

Conveyor systems have proven themselves as more than just material movers. They are central to scaling appliance production effectively. From boosting output and improving safety to supporting lean practices and automation, conveyors deliver real business value. Efficiency, agility, and sustainability all begin with the right systems in place.

Now is the time for manufacturers to rethink their conveyor strategy. By partnering with innovators like SanHok, companies can build production lines that are efficient today and ready to grow with tomorrow’s demands.