Industrial hoses are flexible, strengthened tubes businesses use to move gases and fluids. They are made of rubber, PVC, polyurethane, and metal and can move chemicals, oil, steam, water, and air.

Composite and rubber hoses are the most popular and used in most fields. Rubber hoses are better for lifting and releasing fluids, gases, and steam. However, composite hoses are better for moving chemicals, oil, and other hazardous materials. This is one way that plastic and rubber hoses are different.

This article will help you decide between composite hoses and rubber hoses.

What are Composite Hoses?

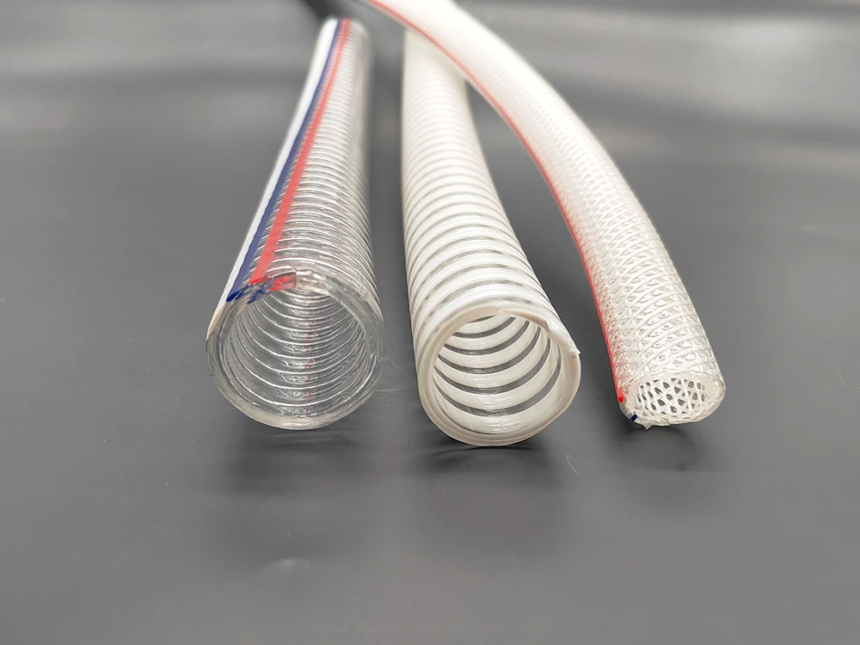

Composite hoses, which are bendable and light, are made from many layers of thermoplastic films and materials. An internal wire or helix holds these layers together. We have already seen that these hoses can be used for many purposes, such as moving chemicals, oil, and other dangerous materials.

Composition of Composition Hoses

Standard composite hose is made of:

Barrier: This layer keeps the media moving through the hose from interacting with the outside world. Aluminum foil, nylon film, or polyester film are often used.

Reinforcement: The strengthening layer makes the hose more robust and stable. It is made of polyester, aramid fibers, or nylon.

Outer: The outer layer protects the inside parts from damage. It’s often made of polyurethane, rubber, or PVC.

What Is Rubber Hose?

A rubber hose comes in two main styles: a uniform style, which only has the rubber hose and no other layers, and a three-layer style:

Composition of Rubber Hoses

Inner: Rubber tubing serves as the media’s conduit on the inside. Any harm that the media does to this layer will not show up.

Outer: The outside layer keeps the inside layers safe from the outside world.

Middle: A wire is twisted or made for the middle layer and goes around the inner layer, strengthening the tube.

Composite Hoses Vs Rubber Hoses:

Both composite and rubber hoses have pros and cons. Here is a general comparison you should consider when choosing a hose for a task. Some hoses from different makers may be slightly different.

Cost: A rubber hose costs less than a plastic hose of the same size.

Availability: The ability to get rubber hoses are usually more accessible and familiar than composite hoses.

Sizing: Rubber hoses come in more sizes than composite hoses.

Resistance to chemicals: Chemicals damage rubber hoses more than composite hoses. It makes them better for use with dangerous media.

Permeation: Generally, composite hoses let less water through than rubber hoses.

Flexibility: With a composite hose, the pieces can slide over each other when the hose moves. Composite hoses are more bendable than rubber hoses because of this.

Abrasion resistance: Composite hoses are more likely to break under pressure than rubber hoses.

Weight: A composite hose the same size as a rubber hose can be up to 30% lighter.

Resistance to temperature: Various minimum and maximum temperatures can be built into composite and rubber hoses.

Composite Hoses Vs Rubber Hoses: Applications

Composite Hoses Application

- Composite hoses can endure severe maritime conditions in ship-to-shore and ship-to-ship applications. For instance, they help transport gasoline from land to sea.

- Composite hoses help transfer a wide range of items carried by road and rail tankers, including petroleum products, chemicals, and more.

- Composite hoses transport chemicals and other harmful items across an industrial facility. They may move media between storage tanks and other places.

Rubber Hoses Applications

- One everyday use for food-grade silicone rubber hoses is in the food processing industry. This form of rubber hoses satisfies the standards of regulatory agencies like the FDA for food quality. Rubber hoses used in the food processing industry must also be flexible and have enough thick walls to avoid leaks.

- Oil- and grease-resistant rubber hoses are standard in gasoline-powered vehicles.

- Silicone rubber hoses are ideal for the pharmaceutical industry. They are odorless, non-toxic, chemical resistant, temperature stable, and inert.

- Rubber hoses are great for transporting materials like grain and feed in agriculture.

Comparison Between Composite Vs Rubber Hoses: Summary

Composite hoses are lightweight, flexible, and resistant to various chemicals. Their excellent chemical resistance drives them ideal for use in the chemical and petrochemical industries, among other places. Composite hoses are perfect for high-pressure uses because of their great temperature and pressure resistance. Because they do not conduct static electricity, they may be used safely in areas with explosives.

Rubber hoses are long-lasting, adaptable, and flexible. Their resistance to high temperatures makes them perfect for steam transfer and other high-temperature uses. Additionally, rubber hoses are durable and resistant to wear and tear. This feature creates an excellent choice for demanding industries like construction and mining. Rubber hoses are also great for outdoor uses since they are weather-resistant.

Rubber hoses are also versatile in industrial applications due to their compatibility with various fittings and connectors, such as aeroquip hose fittings, which ensure secure and reliable connections in complex hydraulic systems.