Choosing the right drug naming machine is a basic choice for any business in the pharma business. The significance of exact, effective, and dependable naming couldn’t possibly be more significant, as it straightforwardly influences administrative consistency, brand trustworthiness, and functional proficiency. Whether you are a startup wandering into the drug area or a laid-out organization hoping to update your current hardware, understanding the subtleties of various naming machines is fundamental. This guide expects to give an extensive outline of the critical elements to consider while picking a pharma naming machine provider and the kinds of machines accessible on the lookout.

Understanding the Importance of Pharma Labeling

Before jumping into the determination cycle, it’s urgent to comprehend the reason why naming is so significant in the drug business. Labeling on drug items are not only for marking or promoting; they assume an essential part in guaranteeing patient security and administrative consistency.

Here are a few justifications for why picking the right pharma labeling machine supplier is indispensable:

- Administrative Consistence: Drug items are dependent upon severe guidelines forced by bodies like the FDA (Food and Medication Organization) in the US, EMA (European Prescriptions Office) in Europe, and others all around the world. These guidelines direct what data should be remembered for the mark, for example, measurement guidelines, fixings, lapse dates, and that’s only the tip of the iceberg. Rebelliousness can prompt serious punishments, reviews, and harm to the organization’s standing.

- Patient Wellbeing: Precise marking guarantees that patients get the right drug and dose. Mislabeling can prompt medicine blunders, which can have serious, even lethal, outcomes.

- Brand Uprightness: Steady and great marking keeps up with brand respectability and trust. Clear, decipherable, and proficient marks consider emphatically the organization and its items.

- Functional Effectiveness: Computerized marking machines can fundamentally upgrade the proficiency of the creation cycle, lessening physical work, limiting blunders, and expanding throughput.

Types of Pharmaceutical Labeling Machines

There are various labeling machines available, each designed for specific container shapes and production speeds.

Here’s a breakdown of the most common types:

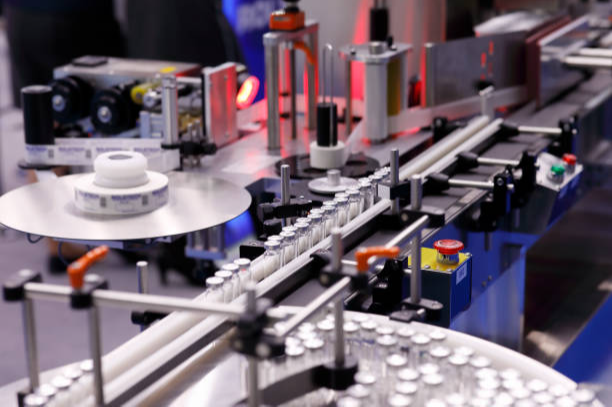

- Fold-Over Labeling Machines: Ideal for labeling cylindrical containers or vials. These machines apply labels that wrap around the entire body of the container, ensuring complete coverage. They’re commonly used for vials, ampoules, and bottles in the pharmaceutical industry.

- Top and Bottom Labeling Machines: As the name suggests, these machines apply labels to the top or bottom surfaces of products. They’re suitable for flat containers, boxes, and pouches. This type is often used for blister packs and flat containers.

- Front and Back Labeling Machines: These machines can apply labels to both the front and back of a container simultaneously. They’re typically used for rectangular or square bottles and containers, providing complete labeling on both sides.

- Wrap-Around Labeling Machines: These machines apply labels that wrap around the entire container, similar to fold-over machines, but may be used for a wider variety of container shapes.

- Print and Apply Labeling Machines: These machines combine printing and labeling in one step. They’re highly efficient for applications requiring variable information printing, such as batch numbers, expiry dates, and barcodes. This type of machine is crucial for ensuring traceability and consistency in the pharmaceutical industry.

- Tamper Evident Labeling Machines: These machines apply labels that show evidence of tampering if the product is opened. They are essential for guaranteeing the integrity and safety of pharmaceutical products, providing an extra layer of protection against tampering and counterfeiting.

Common Pharmaceutical Labeling Machines

Building on the different types of labeling machines, here’s a closer look at some specific machines commonly used in the pharmaceutical industry:

- Vial Labeling Machines: These are specialized fold-over labeling machines designed for the precise application of labels on cylindrical vials. They ensure complete coverage and are ideal for high-speed production lines.

- Ampoule Labeling Machines: Similar to vial labeling machines, these are designed for the accurate labeling of ampoules, another common pharmaceutical container.

- Syringe Labeling Machines: These machines handle the unique shape and size of syringes, applying labels efficiently and precisely.

- Auto-Injector Labeling Machines: These machines cater to the labeling of auto-injectors, which are pre-filled syringes with automatic injection mechanisms. They ensure proper labeling on these complex devices.

- Box Labeling Machines: These machines, often top and bottom or wrap-around applicators, are used for labeling cardboard boxes containing medication. They can handle a variety of box sizes and shapes.

These examples highlight the variety of labeling machines used in the pharmaceutical industry to ensure accurate, efficient, and tamper-evident labeling of medications.

Key Factors to Consider When Choosing a Pharma Labeling Machine Supplier

Choosing the right pharma labeling machine supplier is essentially as significant as picking the actual machine.

Here are a few vital elements to consider:

- Quality and Dependability: The provider ought to offer excellent machines that are solid and sturdy. Check for client surveys, tributes, and contextual analyses to measure the presentation of their machines in certifiable situations.

- Consistency with Guidelines: Guarantee that the machines given by the provider satisfy all important administrative guidelines. The provider ought to be educated about the administrative necessities in various business sectors and guarantee their machines are consistent.

- Customization and Adaptability: The provider ought to offer machines that can be modified to meet your particular requirements. This incorporates the capacity to deal with various mark sizes, shapes, and materials, as well as the mix of extra highlights like vision frameworks for quality control.

- Specialized Help and Preparing: Search for providers that offer thorough specialized help and preparation. This incorporates establishment, support, investigation, and administrator preparation to guarantee smooth activity and negligible margin time.

- Cost and return on initial capital investment: Think about the expense of the machine and the possible profit from speculation (return for capital invested). While it could be enticing to go for the least expensive choice, taking into account the drawn-out advantages and reserve funds that come from putting resources into a top-notch, proficient machine is significant.

- Notoriety and Experience: Pick a provider with a strong standing and broad involvement with the drug business. Laid-out providers are bound to have a profound comprehension of industry challenges and can give improved arrangements and backing.

The Process of Implementing a Pharma Labeling Machine

Carrying out a new naming machine includes a few stages. Here is an outline of the run-of-the-mill interaction:

Needs Appraisal: Assess your ongoing creation needs and recognize the particular necessities for your naming interaction. This incorporates the kinds of items you want to name, creation volumes, and any administrative prerequisites.

Exploration and Choice: Exploration of various providers and machines, remembering the key variables referenced previously. Demand showings or preliminaries to see the machines in real life and survey their reasonableness for your requirements.

Buy and Establishment: Whenever you’ve chosen a machine and provider, continue with the buy. The provider ought to help with the establishment and arrangement of the machine to guarantee it coordinates consistently with your current creation line.

Preparing: Guarantee that your staff get sufficient preparation on the best way to work and keep up with the machine. This will assist with expanding proficiency and limit the gamble of blunders.

Approval and Consistence: Direct exhaustive testing and approval to guarantee the machine meets generally administrative prerequisites and proceeds true to form. This incorporates checking the precision and nature of the marks applied.

Progressing Upkeep and Backing: Standard support is crucial for keeping the machine moving along as planned. Work with the provider to lay out an upkeep plan and guarantee admittance to specialized help when required.

Future Trends in Pharma Labeling

The drug business is continually developing, as are naming innovations. Here are a few patterns to keep an eye out for:

Savvy Names and IoT: Brilliant marks installed with RFID (Radio Recurrence Recognizable proof) or NFC (Close to Handle Correspondence) innovation can upgrade discernibility and give continuous information on item status. This is especially helpful for checking the store network and guaranteeing the credibility of items.

Practical Naming Arrangements: As maintainability turns into a need, there is a developing interest in eco-accommodating marking materials and cycles. This incorporates biodegradable marks, recyclable materials, and energy-efficient machines.

Robotization and Combination: The pattern towards more prominent computerization and joining with other creation processes is supposed to proceed. Progressed marking machines can be coordinated with ERP (Endeavor Asset Arranging) frameworks, quality control frameworks, and other creation hardware for consistent tasks.

Expanded Reality (AR) and Augmented Reality (VR): AR and VR advancements can be utilized for preparing, giving administrators vivid, involved preparing encounters without the requirement for actual machines. This can improve learning and diminish preparation time.

Man-made brainpower (computer-based intelligence) and AI: man-made intelligence and AI calculations can be utilized to streamline marking processes, foresee support needs, and work on quality control. These advances can break down huge volumes of information to recognize examples and settle on informed choices.

Final Words

Picking the right pharma labeling machine is a basic choice that can fundamentally influence your business tasks. By understanding the various sorts of machines accessible, taking into account key elements while choosing a provider, and remaining informed about industry patterns, you can pursue an educated choice that meets your particular requirements.

Putting resources into an excellent, productive marking machine guarantees consistency and patient security as well as improves your image’s standing and functional proficiency. For more data and to investigate the scope of pharma naming machines, visit the pharma labeling machine provider.