Gas turbine generators play a crucial role in the energy industry, providing reliable and efficient power generation for various applications ranging from industrial to commercial and even residential use. These versatile machines utilize the combustion of fuel to drive a turbine, which in turn generates electricity. In this comprehensive guide, we’ll explore the world of gas turbine generators, delving into their operation, benefits, applications, and best practices for achieving reliable and efficient energy production.

Understanding Gas Turbine Generators

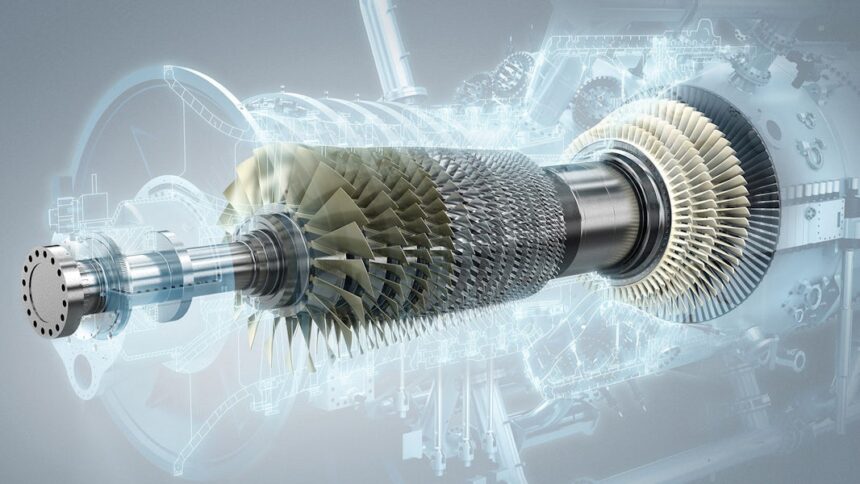

Gas turbine generators, also known as combustion turbines, operate on the principle of converting the chemical energy of fuel into mechanical energy through combustion. This mechanical energy is then used to drive a generator, which produces electricity. Gas turbine generators consist of several key components, including:

- Compressor: The compressor compresses incoming air before it enters the combustion chamber. This increases the air pressure and temperature, preparing it for combustion.

- Combustion Chamber: The combustion chamber is where fuel is mixed with compressed air and ignited. The resulting high-temperature, high-pressure gases expand rapidly, driving the turbine blades.

- Turbine: The turbine is connected to the compressor and generator shaft. As the hot gases flow over the turbine blades, they cause the turbine to rotate, which in turn drives the generator to produce electricity.

- Generator: The generator converts mechanical energy from the turbine into electrical energy. It consists of a rotor and stator, with the rotor connected to the turbine shaft and the stator stationary within the generator housing.

Benefits of Gas Turbine Generators

Gas turbine generators offer numerous benefits including high efficiency, low emissions, rapid startup times, and versatility in fuel options, making them an ideal choice for reliable and cost-effective electricity generation in various industries and applications.

- High Efficiency: Gas turbine generators are known for their high efficiency, especially in combined cycle configurations where waste heat from the turbine is used to produce steam and drive a steam turbine. This allows for overall efficiencies exceeding 50%, making gas turbines one of the most efficient forms of fossil fuel-based power generation.

- Fast Start-up and Ramp-up: Gas turbine generators can start up quickly and ramp up to full load within minutes, making them ideal for providing rapid response to changes in electricity demand. This flexibility is particularly valuable for grid stability and supporting intermittent renewable energy sources.

- Low Emissions: Modern gas turbine generators are designed to minimize emissions of pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. Advanced combustion technologies and emissions control systems help reduce environmental impact while ensuring compliance with regulatory standards.

- Fuel Flexibility: Gas turbine generators can run on a variety of fuels, including natural gas, diesel, kerosene, and biofuels. This versatility allows operators to choose the most cost-effective and environmentally friendly fuel option based on availability and regulatory requirements.

- Reliability and Durability: Gas turbine generators are known for their reliability and durability, with long service intervals and minimal maintenance requirements. This makes them well-suited for continuous operation in demanding industrial and utility-scale applications.

Applications of Gas Turbine Generators

Gas turbine generators find versatile applications in various industries including power generation, aviation, oil and gas, and marine propulsion, providing reliable and efficient electricity generation for both stationary and mobile power needs.

- Electric Power Generation: Gas turbine generators are widely used for electric power generation in both utility-scale and distributed power generation applications. They can be deployed as standalone units or as part of combined cycle power plants to maximize efficiency and reliability.

- Cogeneration and Combined Heat and Power (CHP): Gas turbine generators are often used in cogeneration and combined heat and power (CHP) systems, where waste heat from the turbine is captured and used for heating or industrial processes. This allows for higher overall energy efficiency and cost savings.

- Industrial Applications: Gas turbine generators are used in various industrial applications, including oil and gas production, chemical processing, and manufacturing. They provide reliable onsite power generation for critical processes and operations, reducing dependence on grid electricity.

- Emergency Backup Power: Gas turbine generators are commonly employed as emergency backup power sources for hospitals, data centers, telecommunications facilities, and other critical infrastructure. Their fast start-up and ramp-up capabilities ensure rapid response during power outages or grid disturbances.

Best Practices for Gas Turbine Generator Operation

Ensure optimal performance and longevity of gas turbine generators by implementing regular maintenance schedules, monitoring operational parameters, and adhering to safety protocols to maximize efficiency and reliability.

- Regular Maintenance: Follow manufacturer recommendations for routine maintenance and inspections to ensure optimal performance and reliability. This includes regular checks of fuel and oil levels, filter replacement, and turbine blade inspection.

- Operational Optimization: Implement operational strategies to maximize efficiency and minimize emissions, such as load scheduling, turbine inlet air cooling, and exhaust gas recirculation. Monitor performance parameters regularly and adjust operation as needed to optimize efficiency.

- Fuel Quality Management: Use high-quality fuel with consistent properties to ensure proper combustion and minimize emissions. Regularly monitor fuel quality and perform fuel system maintenance to prevent fuel-related issues.

- Emissions Control: Install and maintain emissions control systems, such as selective catalytic reduction (SCR) and exhaust gas recirculation (EGR), to reduce emissions of pollutants and comply with regulatory requirements.

- Safety Measures: Implement appropriate safety measures, including fire detection and suppression systems, gas leak detection, and emergency shutdown procedures, to protect personnel and equipment during operation.

- Training and Personnel Competence: Provide comprehensive training for operators and maintenance personnel to ensure they have the necessary knowledge and skills to operate and maintain gas turbine generators safely and effectively.

Conclusion

Gas turbine generators are indispensable tools for reliable and efficient energy production across a wide range of applications. Their high efficiency, fast start-up, and fuel flexibility make them well-suited for addressing the challenges of modern energy systems, including grid stability, emissions reduction, and integration of renewable energy sources. By understanding the principles of operation, benefits, applications, and best practices for gas turbine generator operation, operators and stakeholders can harness the full potential of these versatile machines to meet their energy needs reliably and efficiently while minimizing environmental impact. With proper maintenance, operational optimization, and adherence to safety protocols, gas turbine generators can continue to play a central role in powering the world for generations to come.