3/4 plywood is one of the most common types of plywood used in construction and woodworking. Its thickness, durability, and versatility make it an ideal material for a wide range of applications, from furniture building to home construction. Whether you’re a DIY enthusiast, a contractor, or a professional woodworker, understanding what 3/4 plywood is, its benefits, uses, and how to choose the right type is essential for getting the best results for your project.

In this guide, we’ll explore the features, applications, advantages, and considerations when using 3/4 plywood for your next project.

What is 3/4 Plywood?

Plywood is a versatile material made from layers of wood veneer that are glued together, with the grains of each layer running in opposite directions. The result is a strong and durable material that resists warping, cracking, and shrinking.

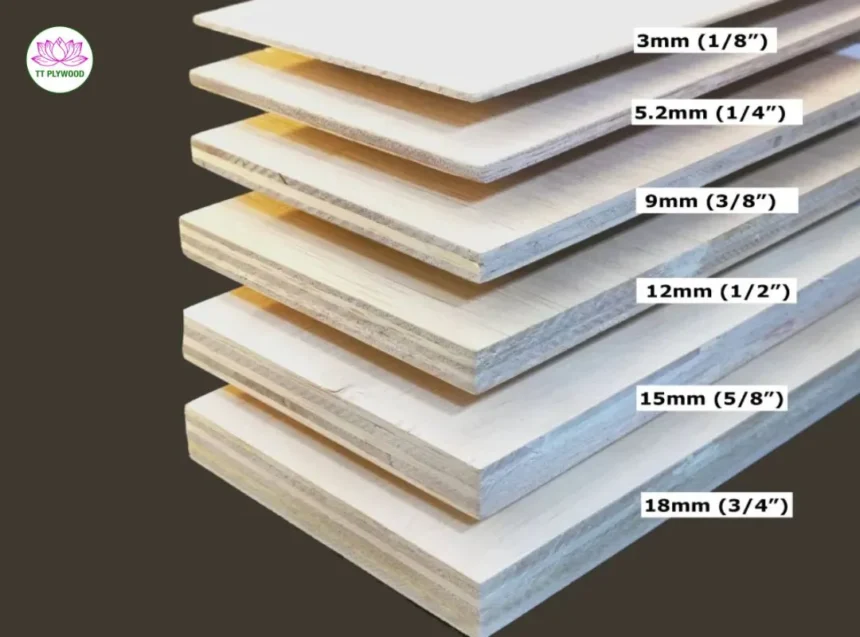

The 3/4 plywood refers to the thickness of the plywood, which is 3/4 of an inch or approximately 19mm thick. This makes it a robust material suitable for many structural and decorative purposes. Plywood thickness can vary widely, with common options ranging from 1/8-inch up to 1-inch thick, but 3/4 plywood strikes a balance between strength and weight, making it a go-to choice for various applications.

Composition of 3/4 Plywood

The structure of 3/4 plywood is typically made up of multiple layers, known as plies. The number of layers can vary, but generally, 3/4 plywood consists of odd layers, such as 5, 7, or 9, with each layer having grains running in perpendicular directions. This cross-layer design provides superior strength, flexibility, and durability compared to solid wood.

Types of 3/4 Plywood

There are several types of 3/4 plywood, each suited for specific applications. When choosing 3/4 plywood, it’s essential to consider the type that best meets your needs.

Softwood Plywood

Softwood plywood is made from softwoods like pine, fir, and spruce. It is widely used in construction, furniture making, and cabinetry because of its affordability and strength. Softwood 3/4 plywood is often used for projects that don’t require a finished, decorative surface but need a sturdy, reliable material.

Applications: Subflooring, framing, shelving, outdoor projects, and building workbenches.

Hardwood Plywood

Hardwood plywood is made from hardwoods like oak, maple, birch, or cherry. It is denser and more durable than softwood plywood, making it ideal for furniture, cabinetry, and other projects where a fine finish is important. Hardwood 3/4 plywood provides a smooth surface that is ideal for staining or veneering.

Applications: High-end furniture, cabinetry, paneling, and decorative projects.

Marine Plywood

Marine plywood is specifically designed for use in environments exposed to moisture, such as boats and docks. It is made from high-quality hardwoods and has additional waterproofing and resistance to rot, making it perfect for applications where durability in wet conditions is essential.

Applications: Boat construction, outdoor furniture, decks, and other high-moisture environments.

MDF (Medium Density Fiberboard) Plywood

MDF plywood is made from compressed wood fibers and resin. While not technically plywood in the traditional sense, MDF is a popular choice for projects requiring a smooth, uniform surface. It is often used for cabinet doors and custom-built furniture.

Applications: Cabinetry, moldings, decorative furniture, and doors.

Benefits of Using 3/4 Plywood

Using 3/4 plywood comes with numerous advantages. Whether you’re building a large construction project or crafting custom furniture, here are the primary benefits of using 3/4 plywood:

Strength and Durability

One of the key benefits of 3/4 plywood is its strength. Plywood is a highly durable material, and the cross-grain design of 3/4 plywood makes it more stable than solid wood. This strength ensures that 3/4 plywood can support heavy loads, making it suitable for applications like shelving, flooring, and cabinetry.

Cost-Effective

Compared to solid wood, 3/4 plywood is often more affordable, especially when used for structural purposes. It offers a good balance between cost and performance, providing high strength and durability without the high price tag of hardwood.

Versatility

3/4 plywood is incredibly versatile. It can be cut into various shapes and sizes, making it suitable for a range of applications. It is easy to work with using standard tools and is often used in both large-scale construction and small DIY projects. From furniture to flooring to walls, 3/4 plywood serves a wide variety of purposes.

Lightweight

Despite its strength, 3/4 plywood is relatively lightweight compared to other materials like solid hardwood. This makes it easier to handle, transport, and install, especially for DIYers and smaller projects.

Resistant to Warping and Shrinking

Unlike solid wood, which is prone to shrinking, warping, and expanding with changes in moisture and temperature, 3/4 plywood maintains its shape over time. This stability is particularly valuable in environments with fluctuating humidity levels, such as basements or attics.

Applications of 3/4 Plywood

3/4 plywood has a broad range of uses across various fields, from home construction to crafting custom furniture. Here are some of the most common applications of 3/4 plywood:

Flooring

3/4 plywood is commonly used for subflooring in residential and commercial buildings. It provides a stable, strong base for other flooring materials like tile, hardwood, or carpeting. Its strength and durability ensure that it can handle heavy foot traffic and the weight of furniture or appliances.

Cabinetry and Furniture

One of the most popular uses of 3/4 plywood is in the creation of cabinetry and furniture. The thickness of 3/4 plywood provides strength and a smooth surface for staining, painting, or veneering. It is frequently used for building custom kitchen cabinets, bookshelves, dressers, and entertainment centers.

Shelving

3/4 plywood is often used for shelving due to its ability to support heavy loads. It is ideal for both home and industrial shelving units and can be used in areas such as closets, garages, and workshops.

Walls and Paneling

For certain types of interior wall paneling or decorative finishes, 3/4 plywood is used. It’s an affordable option for covering large areas, and it can easily be painted or veneered to match any design style. It’s commonly used in basements, garages, and utility rooms.

Outdoor Projects

Due to its durability and resistance to the elements, 3/4 plywood is often used in outdoor construction projects. This includes creating decks, fences, and sheds, especially when using marine-grade plywood, which is designed for outdoor applications and moisture resistance.

Soundproofing and Insulation

3/4 plywood is sometimes used in soundproofing projects. It helps reduce sound transmission when combined with other soundproofing materials like foam or fiberglass. It is often used in recording studios, home theaters, or commercial spaces where noise control is a priority.

How to Choose the Right 3/4 Plywood for Your Project

When selecting 3/4 plywood for your project, it’s important to choose the right type and quality to ensure the best results. Here are some factors to consider when making your decision:

Type of Wood

Consider whether you need softwood or hardwood plywood. Hardwood plywood is typically used for furniture and projects that require a fine finish, while softwood plywood is used for more structural purposes like subflooring and framing.

Grade of Plywood

Plywood comes in various grades, ranging from A (highest quality) to D (lowest quality). For visible surfaces like furniture or cabinetry, choose A or B-grade plywood for a smooth, attractive finish. For structural applications, C-grade or D-grade plywood is sufficient.

Edge Finishing

If you’re using 3/4 plywood for a project where the edges will be visible, ensure that the edges are smooth or that you’re prepared to finish them properly. Some 3/4 plywood comes with pre-finished edges, while others may require sanding and edging to create a clean look.

Moisture Resistance

If your project involves exposure to moisture, consider using marine plywood or pressure-treated plywood that is designed for wet conditions. Standard plywood may not hold up as well in environments with high humidity or moisture.

Conclusion

3/4 plywood is a versatile, durable, and cost-effective material that is essential for a wide range of construction, woodworking, and home improvement projects. Whether you’re building furniture, installing a new floor, or constructing outdoor structures, 3/4 plywood offers a balance of strength, flexibility, and affordability. Understanding the different types of 3/4 plywood, its benefits, and how to select the right one for your project will help ensure that you get the best performance and longevity out of this valuable material.

By choosing the right 3/4 plywood and using it appropriately, you can create beautiful, durable, and functional designs for your home or business.