In factories and processing units, everything depends on how well machines and systems run together. From keeping the right temperature to making sure the fluid flow is just right, a small mismatch can affect the whole line. This is where industrial control valves come into play.

They may look simple, but they do a big job, controlling flow, pressure, temperature, and levels in different systems. And when done right, they save time, avoid waste, and help machines last longer.

Let’s talk about how these valves actually make things more efficient and smooth in real life, without using any heavy terms.

What Exactly Are Industrial Control Valves?

Industrial control valves are gadgets that are applied in the pipes to regulate the movement of liquids or gases. It can either open all the way, close all the way, or vary the flow rate according to what is required in a process.

These valves are typically installed in water systems, oil lines, gas plants, HVAC systems, and food industries, among many other places where the proper flow is important.

They are involved with level sensors, temperature sensors, and pressure sensors to ensure that the operation is running. Some are air-operated (pneumatic), those hydraulic-fluid-operated, and some operate automatically, and hence are powered by nothing outside of themselves.

Types of Control Valves Commonly Used

Control valves come in various forms, and each of them has its role to play based on the system and requirements.

The popular ones on industries are as follows:

1. Air Control Valves

Air Control Valves are operated using compressed air and air control valves are essential in automation and pneumatic systems.

- Control the flow of air or gas

- Used to start, stop, or regulate airflow

- Available in 2-way, 2-position models

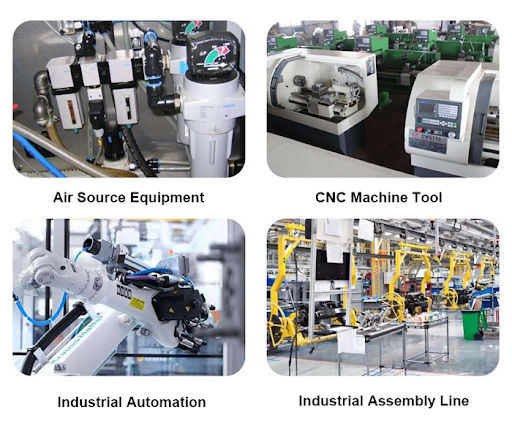

- Commonly found in industrial automation, packaging, and machinery control

2. Flow Control Valves

Flow Control Valves are designed to precisely adjust the flow rate in various systems.

- Regulate liquid or gas flow

- Help control speed, pressure, and system stability

- Widely used in manufacturing equipment, hydraulic-assisted tools, and industrial machinery

3. Level Control Valves

Level Control Valves automatically maintain water levels in tanks and reservoirs.

- Use float mechanisms to adjust water flow

- Require no external power source

- Ideal for irrigation systems, water supply networks, and storage tanks

- Help ensure stable and consistent liquid levels

4. Radiator Thermostatic Valves

Radiator Thermostatic Valves manage the temperature in heating systems by controlling hot water flow.

- Available in both manual and automatic versions

- Help maintain a consistent room temperature

- Improve energy efficiency in home and industrial heating applications

How Do Control Valves Improve Efficiency?

Industrial processes run 24/7, and the systems are interconnected. If one part slows down or fails, the rest also get affected. Control Valves are like small gatekeepers that help avoid this.

Here are some real ways these valves improve performance:

Precise Flow Management

When the flows of fluids are controlled well, all remains on schedule. These valves enable you to regulate the rate to the amount that is required, and this can be said to be just enough. It implies that there will be a reduction in the number of stops, wastage, and fluid production.

Energy Saving

Some valves are built to work automatically without power, such as float valves. This reduces the load on electric systems and helps save energy. Even air-operated valves are quite efficient in terms of pressure control and minimal leakage.

Reduced Manual Work

The trick in contemporary plants is automation. The existence of valves that can either be opened or closed marks the reduction of the amount of manual intervention. This is efficient, it does not involve human error, and other vital jobs can be given attention by the staff.

Flexible Installation

Most valves come with threaded connections and adjustable brackets. This makes them easy to fit into existing setups without needing heavy changes or downtime.

Where Are These Valves Used Most Often?

Control valves are used in many areas across industries. Below are some common applications:

- Manufacturing plants for controlling coolant, oil, and gas lines

- Food and beverage units for managing ingredient flow

- Chemical processing for handling reactive liquids

- HVAC systems for controlling the heating water

- Irrigation systems for automatic water level control

- Automobile factories for pressure regulation in paint and wash stations

These valves are not just useful—they are essential in places where stability and efficiency matter daily.

Why These Control Valves Are Built to Last and Fit Any System

Control valves are built to last thanks to their 304 stainless steel bodies, which resist rust and withstand high pressure, temperature, and frequent use. Their sealed design allows them to work reliably with different fluids and conditions.

They also come in a wide range of sizes—from small options like 1/4″, 3/8″, and 1/2″ to larger industrial sizes such as DN50 up to DN250—making it easy for any system to find the right fit without requiring modifications.

How to Use Control Valves Effectively

Every sort of valve–air control, flow control, level control, or radiator thermostatic–has its own special use. If you choose the right valve, you can guarantee a smooth operation and avoid unnecessary wear.

1. Ensure Valves Are Installed in the Correct Direction

Most control valves have arrows indicating the flow direction. Yet if they are installed in reverse, amenities will decrease, noise will increase, and even damage may be done.

2. Keep Valves Clean and Free from Dirt and Debris

Dirt, rust, sediment, or other impurities can not only affect valve motion but also its sealing properties.

Regularly check pipelines and filters lest you run into the situation of a clogged system.

Regularly examine pipelines and filters in order to fend off instances where the performance of the system might be reduced by blockage.

Regular inspections keep control valves working properly.

1. Employ a Good Filtration System.

A good filter is like a winnow to a ploughing ox. If there is foreign matter in the pipeline, it can cause the seals of moving parts to leak.

An arrangement such as this (see illustration below), combined with a set of filter valves, will effectively purify water supplies and protect equipment from damage.

2. Draw a Lot of air-Departing for Service or on Startup

Before disassembling the valve, make sure it is cool. The media being handled by the valve might be hot, or you may have to prevent contamination and cuts if there are leaks Could Reflect Under certain operating conditions, a decision on whether to vent the valve or let it stand for a while before disassembly must be made.

Do not start at such decisions without obtaining an accurate estimate of how much gas can escape from the valve. One method is to bypass the valve through a temporary line that goes for miles around back to the ground just to be sure-and then shake out the inside.

At the very least, care should always be taken to prevent unintentional mixing of gases, as mixing can cause an atmospheric or local concentration of hazardous substances that could result in grave danger to operators or damage moving components of machinery.

3. Look for Leaks Frequently

Check around fittings, gaskets, and connections. Small leaks that waste energy by draining off pressure are, of course, no asset in any system. Anyhow, they could lead to the entire system’s performance conditions becoming quite unstable.

4. Operate Within Prescribed Range of Pressure and Temperature

Overloading a valve with more than its normal pressure or heat shortens its length of service. Always follow the manufacturer’s safety instructions to use it correctly.

5. Lubricate Moving Parts Regularly

Locomotive and mechanically actuated valves in particular require a regular amount of lubrication.

So They Don’t Wear Out (As Steered Valves Start to Wear over the Long Term) Certain valves, especially those in pneumatic or mechanical systems, need frequent surface cleaning and lubrication. Maintaining smooth movement without wearing away the surfaces becomes difficult otherwise.

Final Thoughts

Control valves don’t just sit quietly in a system—they play a serious role in keeping everything steady, fast, and energy-efficient. With the right type in place, systems stay balanced, output stays on track, and downtime stays low.

Since automatic float valves, which regulate the water level without electricity, are unable to support the working conditions and high productivity, the manufacturing lines are run by air-operated valves.

They can be fitted easily, they are available in a variety of sizes, and they fit most types of flow or pressure systems. Control valves are not the dumbest things to have when constructing or renovating an industrial setup.