The fabrication of stainless steel sheets is a primary/key operation in most industries such as construction, medical equipment, food-grade machinery, and architectural works to mention a few. The corrosion resistant, hygienic and sleek characteristics inherent in this material make it suited in high-performance applications. Nonetheless as useful as stainless steel appears to be, it can be merciless when it comes to fabrication. This article will guide you as an engineer, designer, or contractor to know some of the pitfalls that are encountered in stainless steel fabrication to avert costly remedies, project failures, or poor quality work. Custom sheet metal projects require attention to detail at each of the steps of the sheet metal process including design, cutting, forming, and finishing. The most common fabrication errors in stainless steel sheet metal are described below and their avoidance.

Mis-Evaluation of Stainless Steel Characteristics

Such an oversight as the inability to regard the peculiarities of the mechanics and chemistry of stainless steel can be named as one of the most typical and harmful errors of stainless steel fabrication. A stainless steel is very different to carbon steel or even aluminium in particular aspects such as hardness, thermal expansion, and work hardening. By taking the same processes that are used in milder metals and applying them to stainless steel without considering its special requests warping, cracking or worn tools may ensue. In the case of sheet metal custom solutions, the inappropriate choice of tools or lack of knowledge about the grade used, i.e. between 304 and 316, can have a catastrophic impact on the functionality, as well as the looks. In addition, stainless steel also needs to be treated in a different way in the welding process since high temperatures might destroy the shielding oxide with improper control. Knowledge of the behavior of material under stress and temperature and to prepare it accordingly is essential in getting clean and durable components.

Failure to use Proper Surface Preparation and Finish Techniques

Surface preparation is a more than cosmetic issue, and it is important in the life and performance of fabricated stainless steel parts as well. Among the other steps that are not taken into account in stainless steel sheet metal fabrication and sheet metal custom jobs, one can mention the failure to clean the surface prematurely and after the job is done. Grease and oils as well as carbon steel tool residues can all cause contaminants that will eventually result in corrosion or stains. Cross-contamination can also occur through using identical equipment through both stainless and carbon steels unless the equipment is cleaned in detail. This renders the stainless steel usage futile. Moreover, improper selection of finishing mode, such as brushing, polishing, and bead blasting process, may also lead to irregular surface or poor corrosion resistance. Where a clearly visible area or a hygienic area is involved, an even and appropriate finish is not merely an ornamental option, but a prerequisite. In the selection of finishing, fabricators also should consider the end-use environment, which must suit to the specifications of the project on the technical requirements as well as the conditions of the maintenance in that environment.

Bad Design and Tolerance Planning

The needed design flaws have their origin long before the first sheet gets to be cut. Poorly drawn sketches, absence of any specification of tolerance, or the very complicated shapes may pose a significant roadblock in the fabrication process. One of the most frequent pitfalls of stainless steel sheet metal projects is believing that tight tolerances or even complex bends are something that can be relatively easily accomplished without complicating the project in terms of fabrication or expenditures. Spring-back factor of stainless steel is relatively high, which makes this material stiff, and less than softer metals can be deformed permanently. Failure to put this in consideration during the design phase may result in last components not fitting or positioning correctly. It is in sheet metal custom projects that early communication between designers and fabricators can help predict these problems. Such omissions as a wrong hole size, sharp inside corners, or off-the-books thickness of the materials may cause delays and incur expenditures. It is a good recommendation to engage the fabricator on the design review process so that the plans could be aligned to the current capacity of the manufacturing process. With proper planning the process of rework is lessened and there is more likelihood to produce exact, operational components that achieve their anticipated functions.

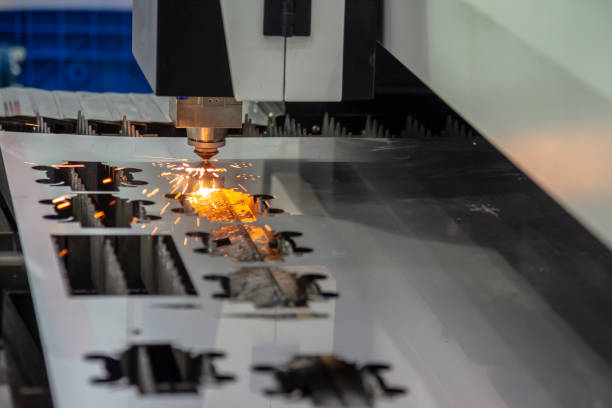

Employment of the Inappropriate Tools or Equipment

The other serious trap is the use of tools and equipment which are not optimized on stainless steel. It is common especially in the smaller shops which deal with the various types of metals using few resources. Stainless steel is more harsh on the tooling, so the low-grade cutting knives or press brakes are not properly reinforced, and some wear may occur to the equipment or in the non-finishing form of rough edges and burrs. In stainless steel fabrication of sheet metal where the volume of work is large, then incorrect tool use may impair efficiency and cause variation in batch production. Also, incorrect lubrication or incorrect cutting speed might result in discoloration, burns or warping which might not only invite loss in the visual appearance but also reduce corrosion resistance. Sheets metal custom shops are aware of the need to keep tools sharp, have brushes and clamps made of non ferrous material, and employ non-reactive cutting fluids on the steel. Proper investment in the appropriate technology and training will maintain the integrity of the final output whilst at the same time lower the long term operation cost.

Omitting Quality Control and Post Fabrication Testing

Quality control is not something that can be done as luckily. The most common inaccuracy in stainless steel fabrication projects is the use of weak quality checks at every step; starting with cutting and forming, assembly and finishing. Poor inspection procedures may leave dimensional errors, flaws on the surfaces, or even structural flaws unnoticed until the very final installation phase, thus causing issues during the later construction phases. These negligence are even more dangerous in a controlled industry such as food processing or healthcare, where stainless steel is typically used as it is required by deep sanitation standards. Post-fabrication inspection is necessary in sheet metal custom jobs where the demanding standards are usually higher and the demands of accuracy and performance are higher. Quality control procedures should consist of dimensional checks, weld tests, uniformity of the surface finish, and tests that would be required to examine corrosion resistance where necessary. Recording and monitoring every procedure throughout the manufacturing process will not only make sure we have the same outcome but also gain clientele confidence based on durability and compliance. The use of accurately calibrated measuring equipment and the strictness to industry rating like ISO or ASME ratified equipment also enhances reliability of your fabrication process.

Stainless steel sheet fabrication can produce components of a superior construction and function as well as being aesthetically pleasing, when addressed with the scientific knowledge and implementation. Nevertheless, to achieve a positive result, it is important to learn how to avoid the above pitfalls that constitute the common practice. Be it oversized industrial constructions or detail-oriented architectural features, sheet metal custom solutions can be highly improved with pensive material handling, quality requirements, and preference of artisan workmanship. The combination of stainless steel sheet metal fabricating and sheet metal custom work requires a high level of paying attention to details. Proper pre planning, the right equipment, cleanliness, and working hand in hand with professionals who are experienced can guarantee all projects to surpass expectations in the long run in performance, usability and finishes.