Introduction to Sodiceram and its History

Sodiceram is making waves in the world of materials, capturing attention for its unique properties and versatility. But what exactly is sodiceram? This innovative material has a rich history that dates back decades, evolving to meet modern needs across various industries. As we explore the fascinating journey of sodiceram, you’ll discover why it’s becoming increasingly popular among manufacturers and consumers alike. From its creation process to its diverse applications, let’s dive into everything you need to know about this remarkable material that’s reshaping how we think about production and sustainability. Get ready to uncover the secrets behind sodiceram!

The Process of Making Sodiceram

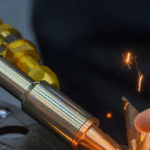

The creation of sodiceram is a fascinating blend of art and science. It begins with carefully selected raw materials, including clay and mineral additives. These components are mixed to achieve the desired consistency.

Once blended, the mixture undergoes shaping through various methods like pressing or casting. This stage requires precision to ensure uniformity in size and texture. After shaping, pieces are dried at controlled temperatures to eliminate moisture without causing cracks.

Next comes the firing process, where items are heated in kilns at high temperatures. This crucial step transforms the material into a durable ceramic form. The final touches involve glazing or finishing techniques that enhance appearance while providing additional protection.

Each phase of production contributes to the unique properties of sodiceram, making it suitable for diverse applications across multiple industries.

Advantages and Benefits of Using Sodiceram

Sodiceram stands out for its remarkable durability. It withstands high temperatures and harsh conditions, making it ideal for various applications.

Its lightweight nature adds to its appeal. Projects become easier and more efficient, reducing transportation costs and installation time.

The material is also highly versatile. From construction to automotive industries, sodiceram adapts seamlessly across different sectors.

Another significant advantage lies in its aesthetic possibilities. Available in numerous colors and finishes, it enhances the design of any project without compromising on functionality.

Furthermore, sodiceram’s resistance to chemicals ensures longevity. This characteristic minimizes maintenance efforts and associated costs over time.

With excellent thermal insulation properties, it improves energy efficiency too. Buildings utilize less energy for heating or cooling when this material is incorporated into their design.

These benefits make sodiceram a preferred choice among architects and engineers alike. Its unique combination of qualities sets it apart from conventional materials.

Different Applications of Sodiceram in Various Industries

Sodiceram has carved a niche across multiple industries due to its unique properties. In construction, it’s prized for durability and thermal insulation, making it ideal for energy-efficient buildings.

In the automotive sector, manufacturers utilize sodiceram in components requiring high strength and lightweight characteristics. This enhances fuel efficiency while maintaining performance standards.

The electronics industry also benefits from sodiceram’s excellent dielectric properties. It’s used in capacitors and insulators, supporting advancements in technology.

Moreover, the healthcare field sees applications of sodiceram in medical devices. Its biocompatibility ensures safety when interacting with biological systems.

Even the aerospace industry finds value in this material—its resistance to extreme temperatures makes it suitable for engine parts and structural components that demand reliability under pressure. The versatility of sodiceram continues to inspire innovation across diverse fields.

Comparing Sodiceram to Other Materials

Sodiceram stands out when compared to traditional materials like ceramic or porcelain. Its unique composition offers enhanced durability and resistance to various environmental factors.

Unlike standard ceramics, sodiceram boasts a lower porosity rate. This characteristic allows it to withstand moisture without the risk of damage or mold growth.

When looking at weight, sodiceram is lighter than many conventional materials. This feature makes it easier to handle and install in diverse applications.

Moreover, sodiceram’s thermal properties are impressive. It can endure extreme temperatures without compromising its structural integrity, making it suitable for high-heat environments.

In contrast, some materials may require special care or treatments over time. Sodiceram typically demands less maintenance due to its robust nature and resistance capabilities.

This material’s versatility opens up opportunities across multiple industries while ensuring long-lasting performance.

Sustainability and Environmental Impact of Sodiceram Production

Sodiceram stands out as a sustainable option in material production. Its manufacturing process emphasizes minimal waste and energy efficiency, aligning with eco-friendly practices.

The raw materials used are often locally sourced, reducing transportation emissions. This local approach not only supports community economies but also lowers the carbon footprint associated with shipping.

Moreover, sodiceram is designed for durability and longevity. Products made from this material require less frequent replacement, leading to decreased consumption over time.

Recyclability is another significant aspect of sodiceram. At the end of its life cycle, it can be repurposed or recycled into new products without compromising quality.

By prioritizing sustainability throughout its lifecycle, sodiceram proves that innovation can go hand-in-hand with environmental stewardship. Its commitment to responsible production makes it an appealing choice for businesses focused on sustainability initiatives.

Future Developments and Innovations in Sodiceram Technology

The future of sodiceram technology is poised for exciting advancements. Researchers are exploring enhanced formulations that could improve strength and durability while reducing weight. This would open new possibilities in various industries.

Smart materials integrated with sodiceram may soon emerge, enabling real-time monitoring of structural integrity. These innovations could revolutionize safety standards across construction and manufacturing sectors.

Additionally, the potential for 3D printing with sodiceram is gaining traction. This technique can create intricate designs that traditional methods struggle to achieve, pushing creative boundaries further than ever before.

Sustainability remains a key focus in these developments. Efforts to source raw materials responsibly will continue, aligning production practices with environmental goals.

As technology evolves, partnerships between manufacturers and tech companies may foster groundbreaking applications that were previously unimaginable. The landscape of sodiceram continues to expand, promising an intriguing journey ahead for this versatile material.

Conclusion: Why Sodiceram is the Material of

The world is evolving, and so are the materials we use. Sodiceram stands out as a remarkable innovation in this landscape. Its unique blend of durability, versatility, and sustainability makes it an appealing choice across various industries.

From construction to electronics, sodiceram offers unmatched performance. Its resistance to heat and moisture sets it apart from traditional materials. This quality contributes to its longevity and minimal maintenance requirements.

Moreover, sodiceram aligns with today’s environmental priorities. The production process minimizes waste and energy consumption, making it an eco-friendly option for manufacturers seeking sustainable solutions.

As technology advances, the future holds exciting possibilities for sodiceram applications. Ongoing research continues to explore new ways to enhance its properties further while maintaining its commitment to sustainability.

Sodiceram is not just a material; it’s a testament to what modern engineering can achieve when innovation meets responsibility. As industries shift towards more efficient practices, sodiceram will likely play a pivotal role in shaping our future infrastructure and products.