Resins are the most important components of a 3D printer because they allow your desired output to exist. It is a 3D printing additive manufacturing technology that uses liquid resins to create various objects.

But with thousands of resins on the market, where does quality come into existence? Are all 3D printer resins the same, and which resin is the best for your 3D printer? Let’s find out!

The Role of Resin in 3D Printing

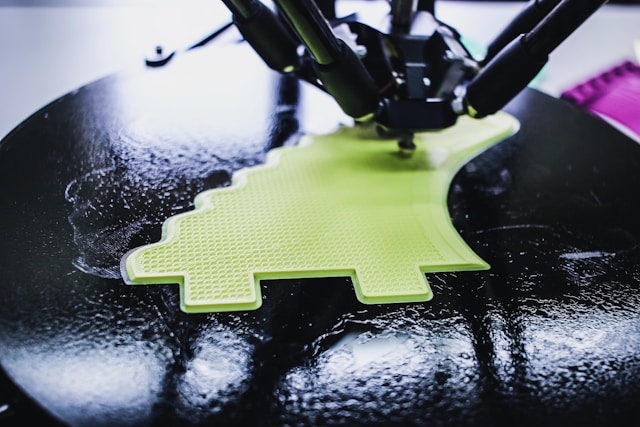

Resin breathes life into vat polymerization 3D printing technologies like Digital Light Processing (DLP) and Stereolithography (SLA). However, unlike the regular filament used in fused deposition modeling (FDM) printing, resin starts off as a liquid photopolymer.

Yes! You’ve guessed it right. In most resin 3D printers, the process starts when the build platform is filled with liquid resin materials. That’s where the 3D printer releases light to create each object layer.

Moreover, as the light passes through that vat and curing layer, the liquid resin turns into solid pieces that would ultimately become the final product from a 3D printer. However, different 3D printing technologies achieve different results with resins.

Here’s how they work.

- Stereolithography (SLA):

SLA is the earliest generation of 3D printing of resin and is quite popular. It uses lasers to convert liquid resin into solid pieces. Moreover, this technology has resin tanks with a platform that uses laser light to convert.

All in all, the SLA printers are perfect for detailed and difficult designs as they can print with a high accuracy even if you want to print large parts.

- Digital Light Processing (DLP):

DLP is another amazing 3D printing technology that uses a shorter wavelength of light to convert the resin material. It is often compared with a projector but the main con comes when we talk about its printing quality.

While its speed is good, the 3D printer would be heavily dependent on the light’s angle, making it difficult to produce complex images. DLP components are also expensive. Overall, it is good for printing simple parts and components.

- Masked Stereolithography (mSLA):

mSLA is the latest generation of SLA 3D printing technology. In this technology, the printer uses masks to control where the light would land on the build plates. Moreover, the masked lights ensure that the light will reach specific areas, making it generate highly detailed prints without much of an issue.

The Impact of Resin Quality on Prints

A high-quality resin produces a masterpiece, while a low-quality one is deemed a failed process. A low-quality resin can put all your efforts into the trash can, while a good-quality resin can bring you results you’ve never even imagined.

Firstly, the main issue with many resins is their inconsistent shrinkage rates. This makes them warp during the printing process, which causes many layers to detach, ultimately ruining the final print.

Another huge issue with resins is their impurities or poor viscosity. This can lead to an uneven surface finish, changing the details and detracting from the final print. Hence, having a resin with good viscosity makes a lot of difference.

But then, we have 3D printer parts that can’t handle wear and tear. This is due to low-quality resins that often make weak, brittle prints that would easily get destroyed under pressure. But what’s the solution to all this?

High-quality resin is the most important part of 3D printing resin, as it serves as the basis for your experiments. However, choosing the right resin depends heavily on your goals and needs. If someone is selling you an all-in-one resin, chances are that resin isn’t going to work out.

So, here’s a complete guide on how to choose high-quality resin based on your requirements.

Choosing the Right Resin

Chitu Systems offers some of the most innovative 3D printing materials, including resins. Selecting the right resin is all about understanding your goals and choosing the right brand. For example, ask yourself whether you’re looking for high-res details for a small action figure or if you want flexibility in your final results.

Then, you need to know about the final print and what they will be used for. And lastly, you need to know the resin’s compatibility with your 3D printer, which is everything. That’s where Chitu Systems comes in. By offering a wide range of high-quality resins, their products go through hard testing to ensure that you’re getting the right product.

- For Functional Gadgets:

For engineer-like features for functional gadgets, you use Chitu Systems’ Conjure Rigid resin, which has perfect mechanical properties for turning, tapping, and milling post-curing. This product is designed for ultra-low shrinkage, non-brittle miniature, and durability, which is superior to a normal resin.

But that’s not all! You can create functional gadgets, OpenRC Parts, and even action figures with a lot of details with Conjure resin.

- For LCD Printing:

But sometimes, you’re looking for a resin that will be okay even if you bend it. That’s where Conjure Tough Resin comes in. It is ideal for LCD/DLP 3D printing. Its unbreakable design makes it perfect for generating items like glass frames, functional gadgets, and more durable designs.

Conclusion

Resins come in all types of brandings, but choosing the right one is crucial for optimal results. A high-quality resin equals better quality when it comes to the results.

If you’re looking for more high-quality resins, you can check the complete catalog of Chitu Systems’ resins here.